- Joined

- Mar 2, 2019

- Messages

- 50

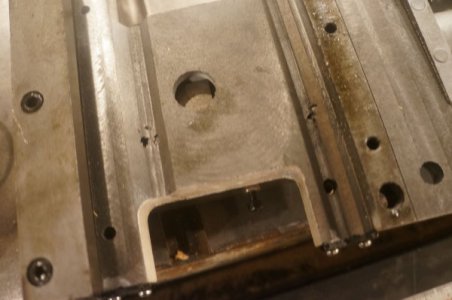

So finally getting down to breaking down my lathe (chinese, yes) and found these casting voids on the underside of the crossslide carrier - which would coincide with the top of the way rails - presumably one of the more important parts of the thing ... what do you think? is this a problem? Should i ask for a replacement part from the seller?