-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

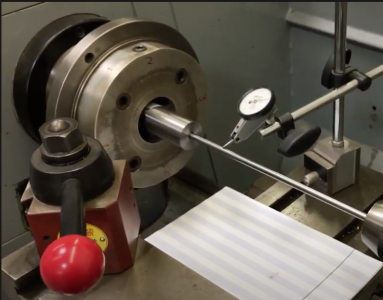

Chambering short barrels in the headstock

- Thread starter LVLAaron

- Start date

- Joined

- Mar 23, 2021

- Messages

- 357

Aaron, thanks for sharing your efforts here.I was going to turn it flush but didn't want to deal with cast iron dust.

I’m very interested in gunsmithing as I’ve been a long time shooter and reloader and now have the means to do some smithing. I’ve got the same lathe as you and would like to start doing some work in this area. Please keep us posted on your efforts and findings with this barrel turning “jig”. I’ve ordered a 6 1/4” D1-5 backplate and will be looking to do something similar to what you have done here.

And thanks to Ken226 as well for your design and input!

- Joined

- Oct 4, 2020

- Messages

- 484

Aaron, thanks for sharing your efforts here.

I’m very interested in gunsmithing as I’ve been a long time shooter and reloader and now have the means to do some smithing. I’ve got the same lathe as you and would like to start doing some work in this area. Please keep us posted on your efforts and findings with this barrel turning “jig”. I’ve ordered a 6 1/4” D1-5 backplate and will be looking to do something similar to what you have done here.

And thanks to Ken226 as well for your design and input!

Put a witness mark on your lathe and on your new back plate. Be sure to turn the face of the backplate true. Mine was out 5-8 thou. (cheapo plate from grizzly)

Get some big aluminum from ebay and get turning. I posted another thread with some links to a counter bore and tools I used.

Here's another fixture that's similar. Really nice design. I was going to skip the back plate on mine but was worried I wouldn't be able to accurately cut the cone shaped register.

Attachments

- Joined

- Mar 23, 2021

- Messages

- 357

That's another interesting take on the same basic design as Ken, but looks to be aluminum instead of steel as Ken used.Here's another fixture that's similar. Really nice design. I was going to skip the back plate on mine but was worried I wouldn't be able to accurately cut the cone shaped register.

Here's another design for holding the barrel between the two ends of the headstock, obviously for longer barrels.

The longer the arm between the two points of adjustment the greater the finesse one can attain in micro adjustments in bore alignment.

Obviously if the barrel will not reach through the spindle bore then a fixture as you are making is necessary.

My thought is why not make a backplate that can have both of these fixtures swapped out depending upon the length of the barrel to be worked on?

- Joined

- Oct 4, 2020

- Messages

- 484

I dont think you'd want to be swapping out back plates. In my mind, once a backplate is attached to something, it's married to it for life.

Some guys like an inboard spider like you just posted, some just use a 4 jaw chuck. I like a 4 jaw because that's what mostly lives in my machine anyway. But with in inboard spider you do work a couple inches close to the spindle.

Some guys like an inboard spider like you just posted, some just use a 4 jaw chuck. I like a 4 jaw because that's what mostly lives in my machine anyway. But with in inboard spider you do work a couple inches close to the spindle.

- Joined

- Mar 23, 2021

- Messages

- 357

If this were a typical chuck type attachment then I could see where swapping back plates would be a potential problem (non Set-True type).I dont think you'd want to be swapping out back plates. In my mind, once a backplate is attached to something, it's married to it for life.

Some guys like an inboard spider like you just posted, some just use a 4 jaw chuck. I like a 4 jaw because that's what mostly lives in my machine anyway. But with in inboard spider you do work a couple inches close to the spindle.

But unless I'm missing something, with this type of fixture, for other than aesthetics, it really doesn't matter if there's a bit of runout as you are centering the barrel inside the four bolts. Whether the body has runout or not should be inconsequential. But again, I may be missing something here.

Drilling both fixtures with the same bolt pattern would make swapping the two bodies back and forth an easy task, and so long as they were indexed properly there should be no more than a .001 of runout. At least that's what I'm thinking.

- Joined

- Mar 23, 2021

- Messages

- 357

Here's a basic but serviceable version of what we are talking about here. Mounting and re-mounting in a 3 jaw is not likely going to be very accurate in terms of TIR, but it doesn't really matter as the ultimate alignment comes from the bolts, not the alignment of the fixture itself.

But then again, I could be missing something here!

But then again, I could be missing something here!