- Joined

- Oct 16, 2019

- Messages

- 6,570

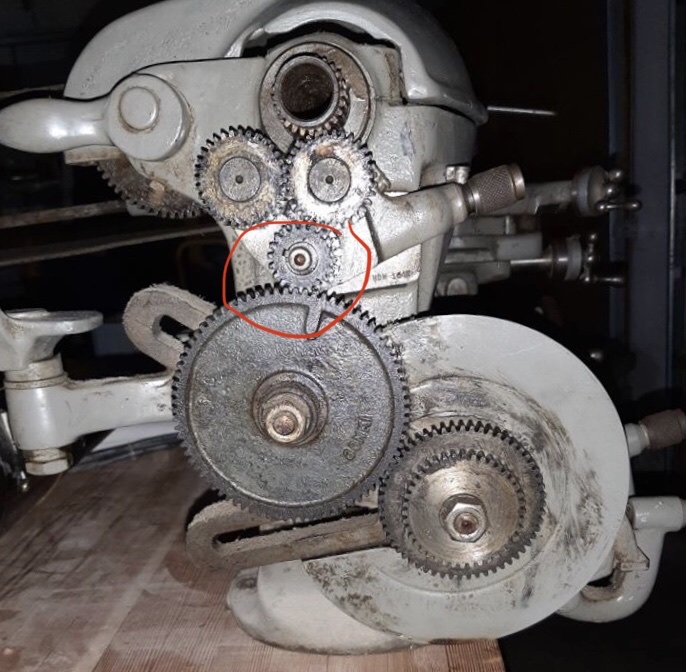

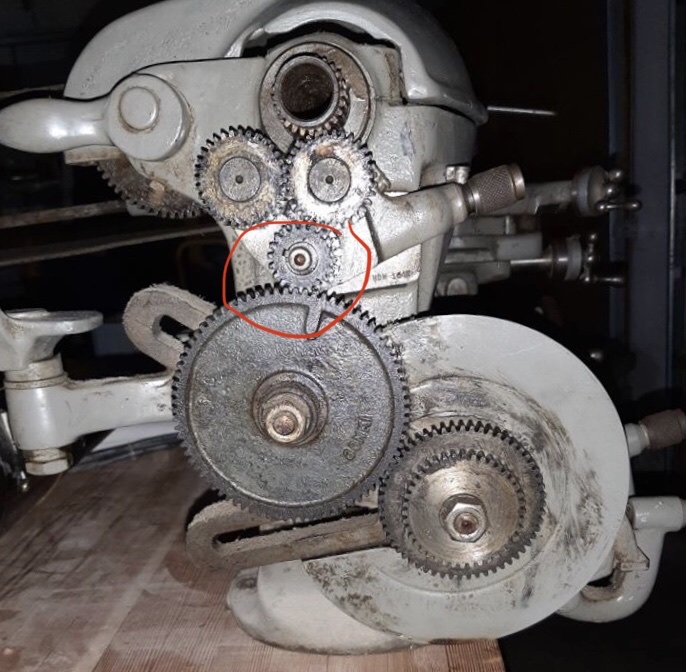

The thread cutting section of “How to run a lathe” gives me the impression that there are gears to be swapped out even if there’s a quick change gearbox.

Specifically the spur gear.

Am I correct or misunderstanding what’s being described.

Sent from my iPhone using Tapatalk

Specifically the spur gear.

Am I correct or misunderstanding what’s being described.

Sent from my iPhone using Tapatalk