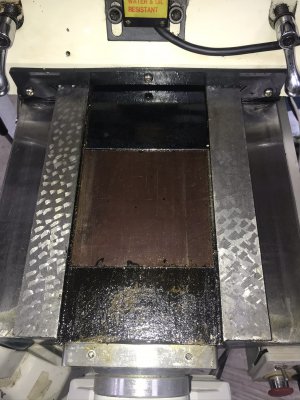

OK, I’m going to try and post a photo......not of the whole machine initially just the saddle slideway (hope that’s what it’s called) if it works out I will take some more pictures of the whole machine. I’ve removed the bellows to have a look and see what condition they are in. The scrapping doesn't to me look to have any wear.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chester 949 Turret Mill, Good Buy?

- Thread starter Deema

- Start date

- Joined

- Sep 2, 2013

- Messages

- 5,090

For your first machine, I'd say you hit the jackpot. The only thing that would make it better, is if you tell us you paid 200 pounds for it. I think you should probably pull off all those power feeds and use it manually for a while so you know how good you have it. Cheers Mike

- Joined

- Sep 25, 2014

- Messages

- 1,107

Clean the coolant ("suds") tank well - my method is a wet dry shop vac, then soapy water - perhaps rinse a couple times. The vac will look very nasty (easily cleaned up) and the machine will look great. My suggestion is that you don't bother running flood coolant - there are a number of other options. I have two coolant fitted lathes and coolant on my small mill - which I have either never used, or not in many, many years - due to the mess and there being other good options. My knee mill (turret mill), very similar in size to your Chester - never was set up with coolant.

My CNC mill is well set up to manage flood coolant (full enclosure, proper drain angles and seams are sealed) and it is wonderful to have the flood and no mess.

Very nice looking machine. Do give us a photo shop tour. It looks like you do a lot of wood working.

My CNC mill is well set up to manage flood coolant (full enclosure, proper drain angles and seams are sealed) and it is wonderful to have the flood and no mess.

Very nice looking machine. Do give us a photo shop tour. It looks like you do a lot of wood working.

Thanks guys, I’ve been playing with the mill a bit. Very happy bunny. The gribd have never been adjusted and neither has the back lash in the nuts. The adjuster screws were still painted up. Now adjusted, seems to be very accurate.

I have two things I’d appreciate your views on. Firstly I’d like to add a DRO. Being new to this, would it be beneficial to have 3 axis, and if so, would you add a scale to the knee or the quill as the third axis. From reading around there seems to be three pickup technologies, tradition glass, magnetic and inductive slides. Any reason to choose one in particular? The range of prices seems phenomenal! Any DROs to avoid / go for? I’m based in the UK.

Finally whats the best coolant option other than flood coolant which I have on the mill?

I have two things I’d appreciate your views on. Firstly I’d like to add a DRO. Being new to this, would it be beneficial to have 3 axis, and if so, would you add a scale to the knee or the quill as the third axis. From reading around there seems to be three pickup technologies, tradition glass, magnetic and inductive slides. Any reason to choose one in particular? The range of prices seems phenomenal! Any DROs to avoid / go for? I’m based in the UK.

Finally whats the best coolant option other than flood coolant which I have on the mill?

Hello Deema, I am in a similar position to you, maybe we can help each other with the learning. My recent acquisition of a Bridgeport which I could not refuse, when I actually bought a surface grinder. has given me a steep learning curve. Small quantities of machine oils are available from:

Graham Wharton, Lube Finder, https://www.lubefinder.com , Tel (UK) : 0800 955 0922

Personally, for the machining I want to do, I don't think the the use of a suds pump is necessary, as time is my own and slow cutting rates are not a problem. Best regards Mike

Graham Wharton, Lube Finder, https://www.lubefinder.com , Tel (UK) : 0800 955 0922

Personally, for the machining I want to do, I don't think the the use of a suds pump is necessary, as time is my own and slow cutting rates are not a problem. Best regards Mike