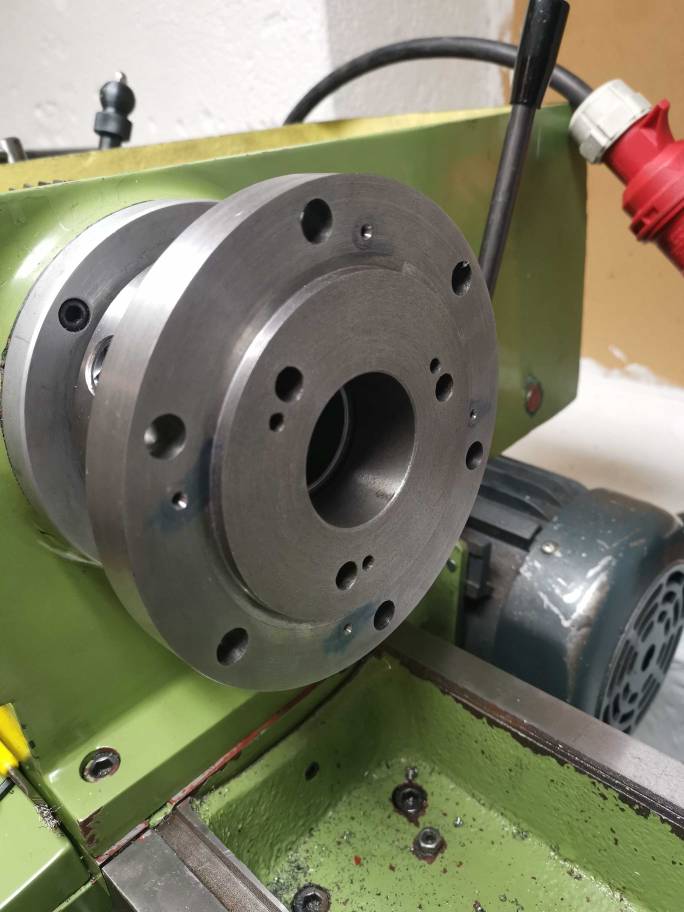

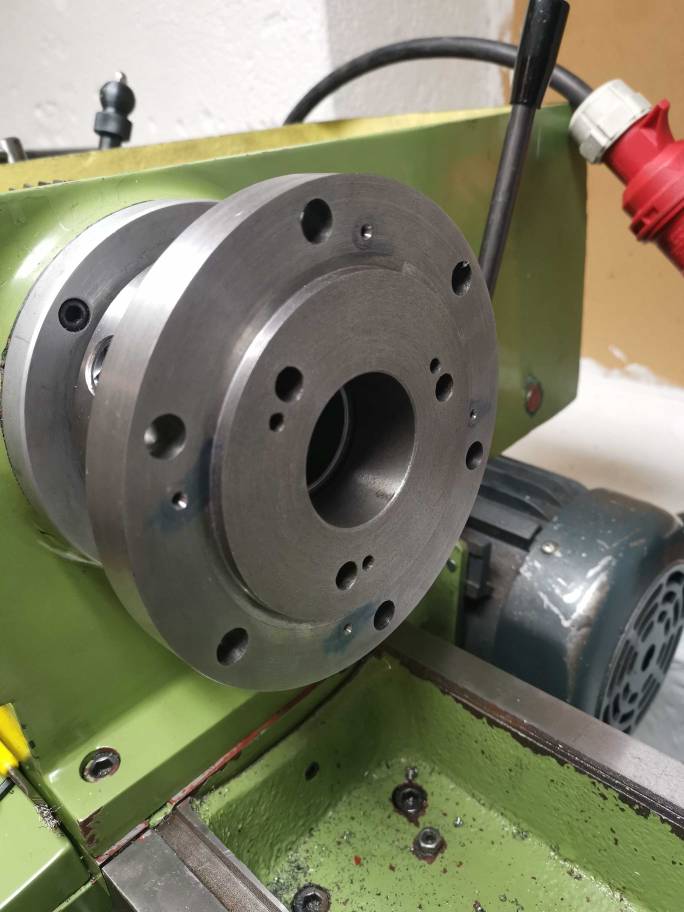

Hello. I want to mount a 4 jaw chuck to this backplate:

The backplate is for another chuck but I can fit both bolthole patterns. The 4 jaw bolts from the front with the threads in the backplate, unlike the other chuck. My question is basically whether I should thread directly into the cast iron backplate or drill oversize holes and make steel plugs with the threads in, that insert from the back of the plate, to increase the strength of the thread? The chuck weighs about 20kg and came with 4 m12 bolts with around 20mm of thread sticking out behind the chuck. The register on the backplate is turned to match the register on the 4 jaw so it should take most of the sideload off the bolts, but I still thought it might be a good idea.

Any input?

Sent from my LYA-L29 using Tapatalk

The backplate is for another chuck but I can fit both bolthole patterns. The 4 jaw bolts from the front with the threads in the backplate, unlike the other chuck. My question is basically whether I should thread directly into the cast iron backplate or drill oversize holes and make steel plugs with the threads in, that insert from the back of the plate, to increase the strength of the thread? The chuck weighs about 20kg and came with 4 m12 bolts with around 20mm of thread sticking out behind the chuck. The register on the backplate is turned to match the register on the 4 jaw so it should take most of the sideload off the bolts, but I still thought it might be a good idea.

Any input?

Sent from my LYA-L29 using Tapatalk