- Joined

- Mar 25, 2013

- Messages

- 4,611

I made a chuck cradle to avoid damaging my D1-3 spindle. I wanted to use a single piece of oak, but I realized it would be too difficult to cut slots to perfectly fit the ways of my lathe. I decided I could more easily make followers for the ways and glue the cradle to those.

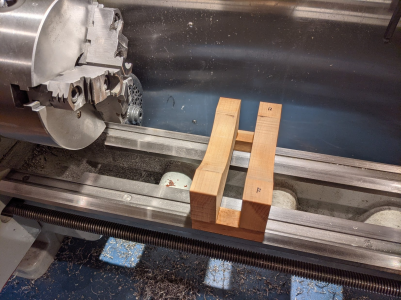

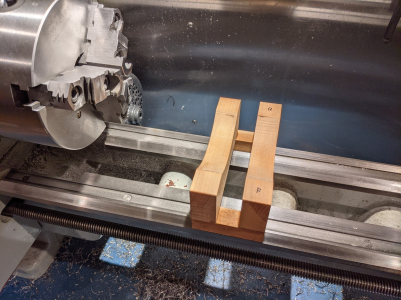

I used the table saw with the blade angled at 45 deg to make this V:

Then I mocked up the cradle on the ways and scribed a line on the cross bars. Then cut that out to form the cradle.

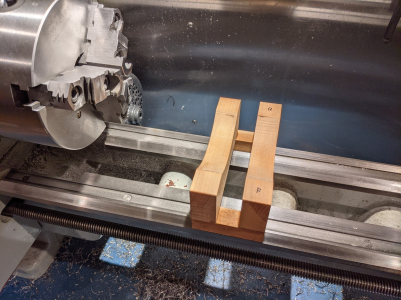

Then I glued the followers to the cradle cross pieces. I actually glued it in place under the chuck to get the alignment right:

Suggestions on what to finish this with? Polyurethane? Oil?

Robert

I used the table saw with the blade angled at 45 deg to make this V:

Then I mocked up the cradle on the ways and scribed a line on the cross bars. Then cut that out to form the cradle.

Then I glued the followers to the cradle cross pieces. I actually glued it in place under the chuck to get the alignment right:

Suggestions on what to finish this with? Polyurethane? Oil?

Robert