- Joined

- Jun 22, 2015

- Messages

- 68

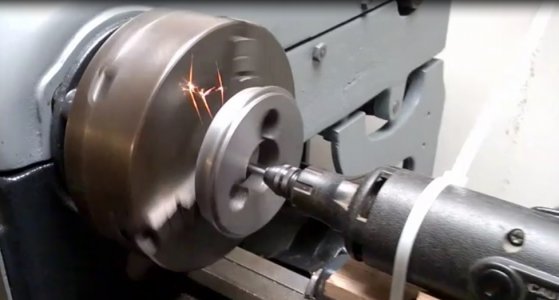

I thought I'd share how I ground my 3 jaw chuck. It was worn pretty bad but now it only has .003 run out. I made a ring to load the chuck and ground the inside of the jaws.

Then I mounted a dremal to the tool holder and ground very slowly.... for like 2-hours!

I'm sure a more solid arrangement would have made quick work of the job but you work with what you have. It worked great... just slow.

Then I mounted a dremal to the tool holder and ground very slowly.... for like 2-hours!

I'm sure a more solid arrangement would have made quick work of the job but you work with what you have. It worked great... just slow.