- Joined

- Apr 23, 2018

- Messages

- 6,510

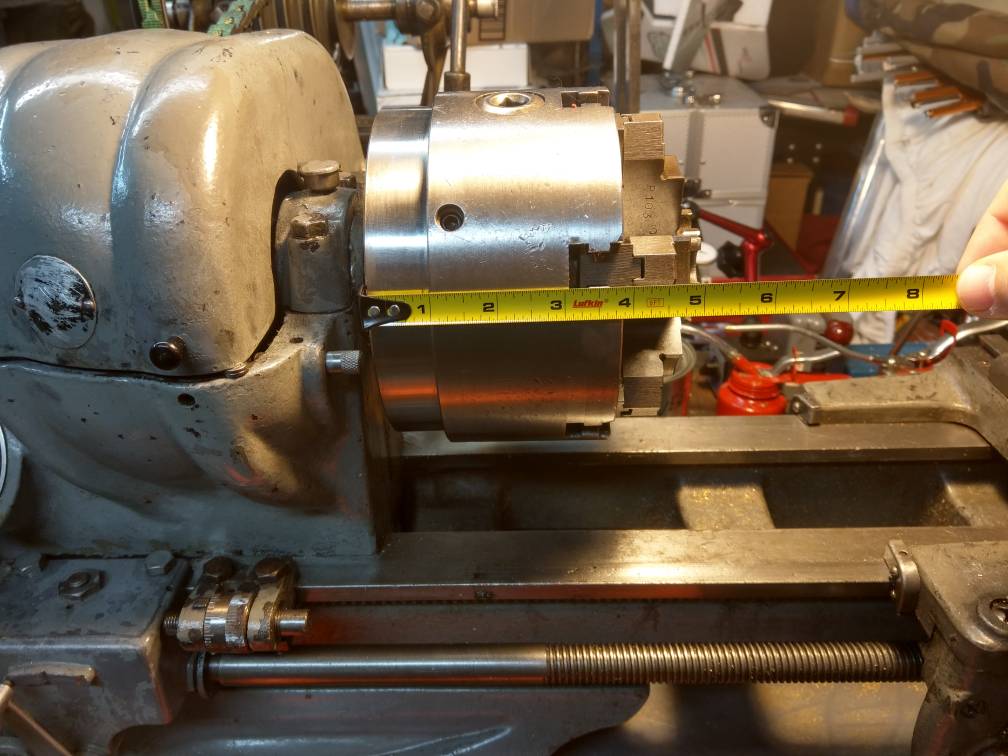

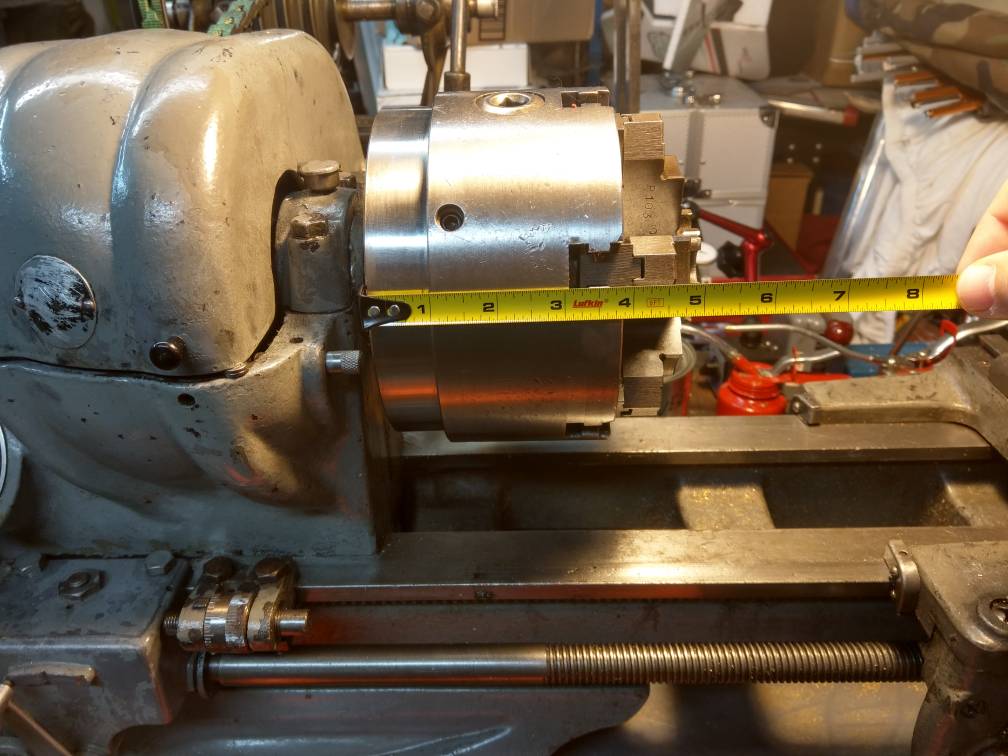

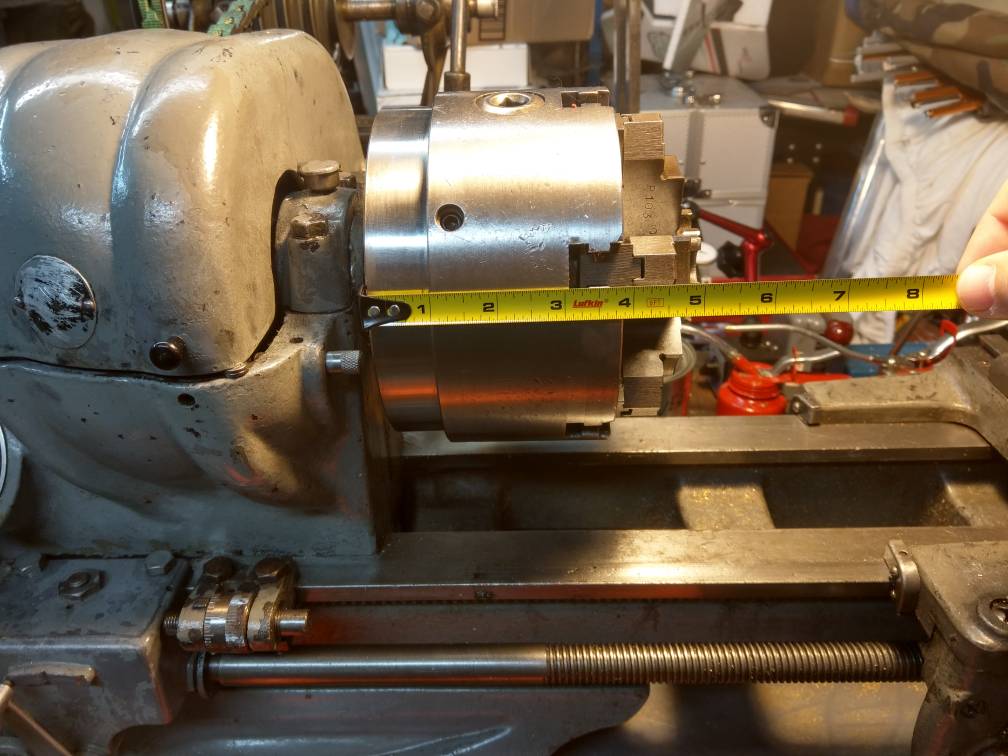

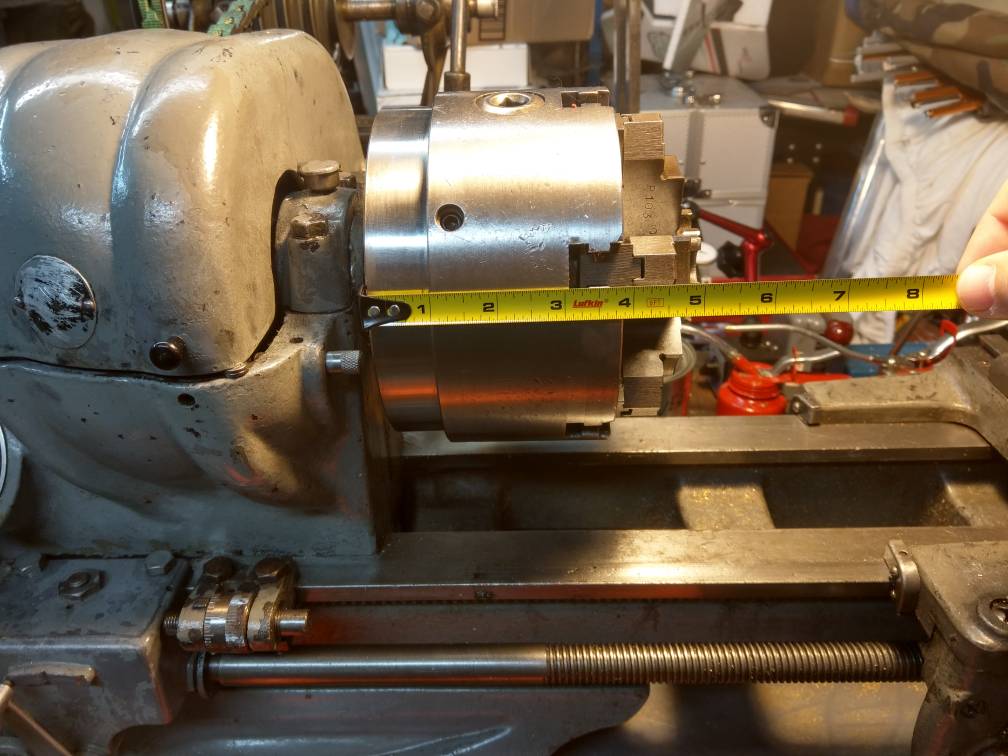

What's the big deal? Sorry, I measured from a different spot.

True. I bought it that way.Your backing plate was pre-mounted, you didn't have to cut the register to fit your chuck?

Well I don’t actually know if it’s a big deal or not. Sometimes I look at something and say to myself,”self, somethings not quite right here.” Perhaps it’s me that’s not quite right. It just seems like a lot of overhang. I don’t know that it is. I guess I’ll find some different thing to worry about for now.What's the big deal? Sorry, I measured from a different spot.