- Joined

- Dec 6, 2012

- Messages

- 2,677

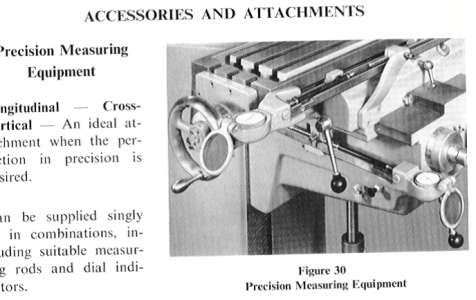

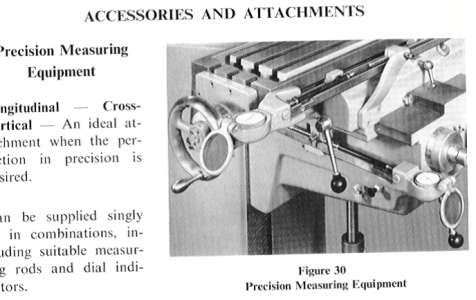

Wondering if anyone on HM has extra parts they'd like to sell, or perhaps take pics and measurements of a Cincy Precision Indicator. I'm particularly interested in the Y axis. I found surplus framework for the factory issue Y axis indicator. But, most of the pieces are missing. Note the pics below. Alternatively, bracket specs for a Y axis "silver bullet" Trav-a-Dial. I'm already using a vintage Trav-a-Dial on the X axis.

Yes, I know a DRO would be more accurate.

Thank you,

Daryl

MN

Yes, I know a DRO would be more accurate.

Thank you,

Daryl

MN