- Joined

- Nov 9, 2018

- Messages

- 377

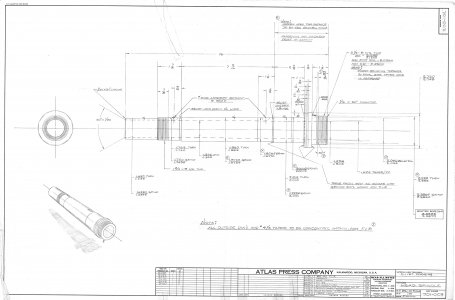

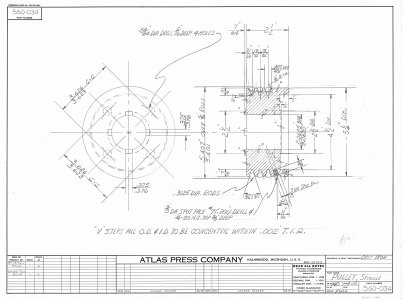

The spindle is exactly 1.5 thou oversized (1.8765) on the clean sections and between 0.5 and 1.5 over in the galled up bearing journal.

I figure I’ve got 3 options:

1) make a cylindrical lap and lap the OD of the spindle true as is. This will probably drop it down to 1 thou over. Or maybe lap it down to just where it cleans the high spots.

2) get it spray welded to build up the surface than lap it.

3) machine a ledge and heat shrink a sleeve over the galled up journal.

The Clausing manual says that the spindle should just slide out with very little effort. That would indicate that they use a very light fit for the bearings.

The hardest part about these options is how to do them without a lathe? I suppose I can try to beg and plead with our shop boss at work to let me use a lathe there. If that fails, maybe I can make a cylinder lap on my mill with the rotary table.

Sent from my iPhone using Tapatalk Pro

I figure I’ve got 3 options:

1) make a cylindrical lap and lap the OD of the spindle true as is. This will probably drop it down to 1 thou over. Or maybe lap it down to just where it cleans the high spots.

2) get it spray welded to build up the surface than lap it.

3) machine a ledge and heat shrink a sleeve over the galled up journal.

The Clausing manual says that the spindle should just slide out with very little effort. That would indicate that they use a very light fit for the bearings.

The hardest part about these options is how to do them without a lathe? I suppose I can try to beg and plead with our shop boss at work to let me use a lathe there. If that fails, maybe I can make a cylinder lap on my mill with the rotary table.

Sent from my iPhone using Tapatalk Pro