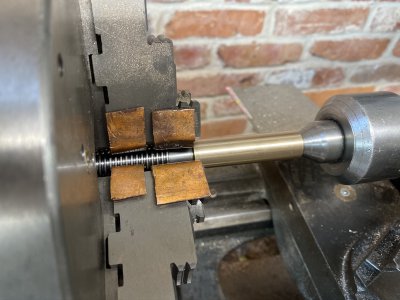

I ordered a new Acme 5/8”-10 LH threaded rod from Roton Products. Finally getting around to making it work on my 5903 lathe.

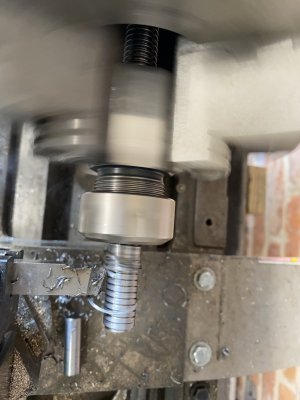

The threaded screw has a dowel pin which attaches it to the Crossfeed dial. The biggest issue is that there is a raised part of the Acme thread which is a bearing surface for a bronze bearing in the housing. Anyway, the diameter of this area is 0.62445

cant show a pic of micing it because I only have two hands. But digital Mitutoyo mic gave me those specs. No way would I get that with my other mechanical mics.

The threaded screw has a dowel pin which attaches it to the Crossfeed dial. The biggest issue is that there is a raised part of the Acme thread which is a bearing surface for a bronze bearing in the housing. Anyway, the diameter of this area is 0.62445

cant show a pic of micing it because I only have two hands. But digital Mitutoyo mic gave me those specs. No way would I get that with my other mechanical mics.

5/8 - 10 Left Hand Acme Lead Screws & Nuts for Power Transmission - Roton Products, Inc.

Shop 5/8 - 10 Left Hand Acme from Roton Products, Inc. View all of our products and shop online for your power transmission needs.

www.roton.com

Attachments

Last edited: