- Joined

- Dec 12, 2016

- Messages

- 493

I have a similar geometry cutter but 1" diameter and that can push my Rockwell mill to the limit.

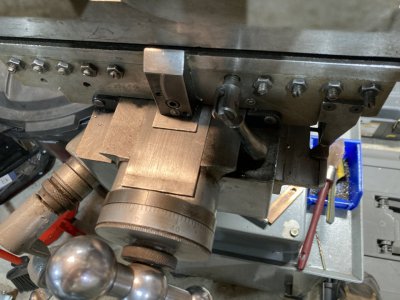

You might want to look at getting one of those 2" diameter 45 degree style cutters (SEHT43) as their geometry is easier on the machine, although they can take light cuts only. Like this one that I happen to have:

glacern.com

glacern.com

Also make sure all ways on your machine are locked down, except for the axis you are moving.

You might want to look at getting one of those 2" diameter 45 degree style cutters (SEHT43) as their geometry is easier on the machine, although they can take light cuts only. Like this one that I happen to have:

Glacern Machine Tools - FM45 Facemills

Glacern Machine Tools manufacturers CNC Machine Vises, Precision Tool Holders, and Indexable Milling Cutters for vertical and horizontal cnc milling machines.

Also make sure all ways on your machine are locked down, except for the axis you are moving.