[h=1]Gears http://www.wentztech.com/metalworking/equipment/clausing-8520-mill/[/h]The gears in the quill can easily be broken. Here are some notes I collected on replacement gears:

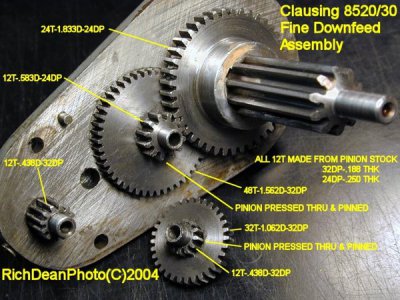

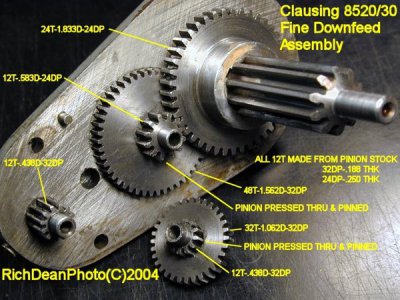

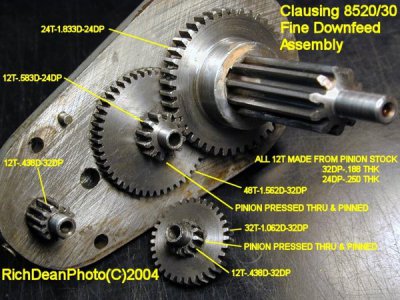

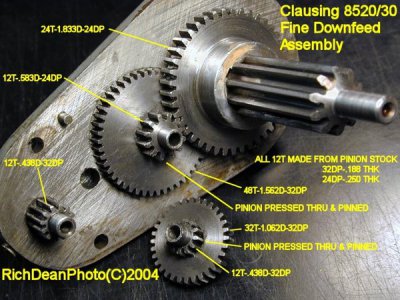

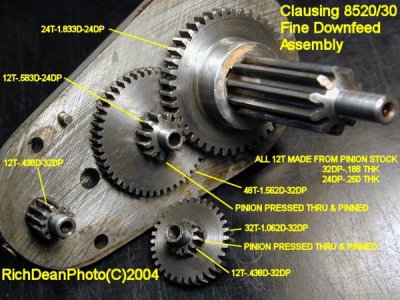

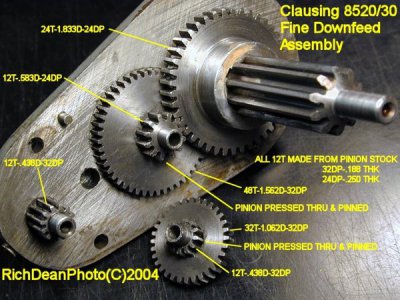

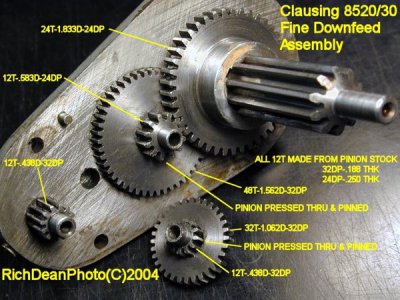

One owner found one of the gears in his mill was marked Boston Gear S-3232.

Their online catalog shows this to be a 32 DP 14.5 degree PA 32 tooth

The last pinion that drives the last gear that slides on the spline is 24 DP instead of 32 DP.

It turns out that the small spur gear portion of the 8520 compound gear (Clausing part 990-065 – cost $66) is a close match to McMaster-Carr part no. 6325 K31. Cost $7.79. A bit of cutting to get the hub thickness down to 1/4 inch, some finish sanding and reassembly using 1/4″ dia. cold rolled stock as a shaft and a broken length of 1/16″ drill bit as a pin to lock the two gears – and everything works. Whole job took about an hour and a half.

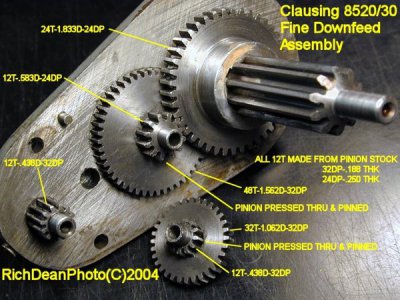

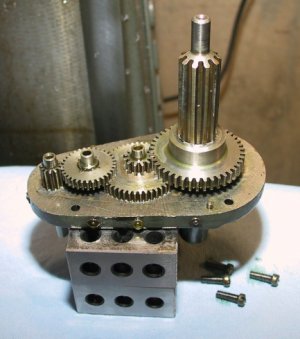

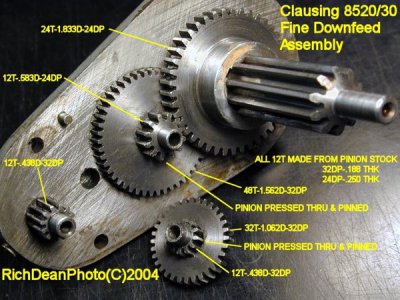

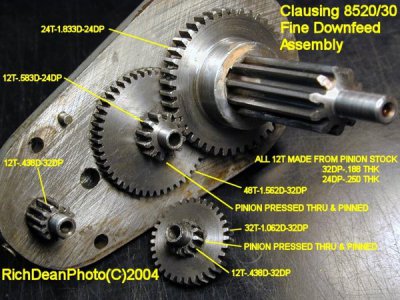

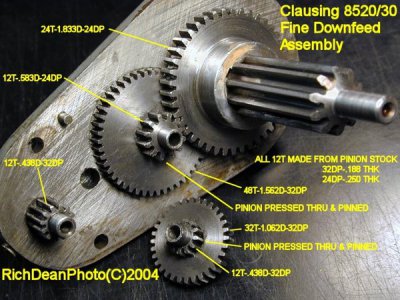

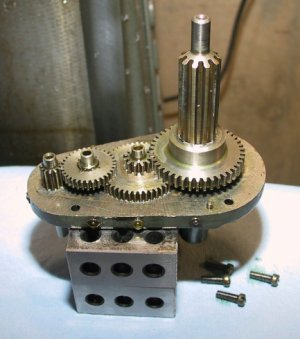

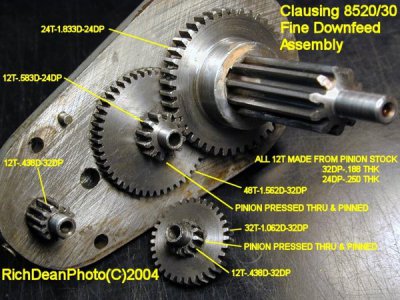

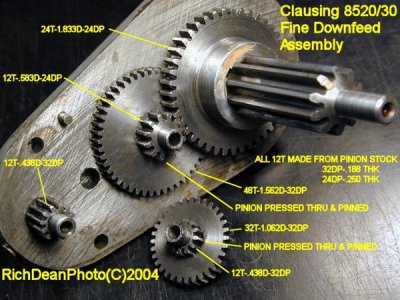

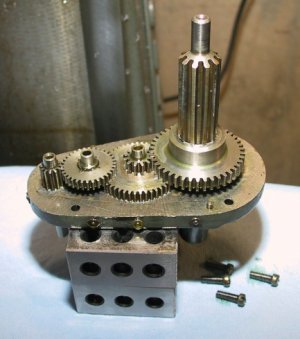

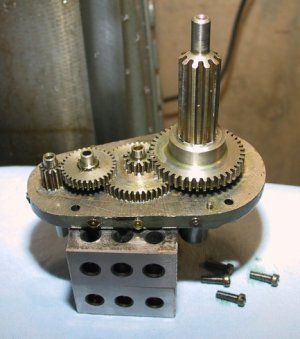

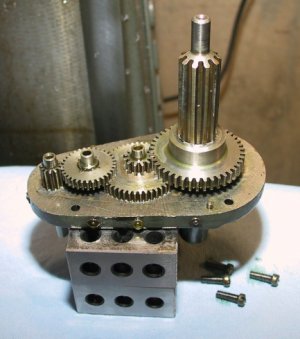

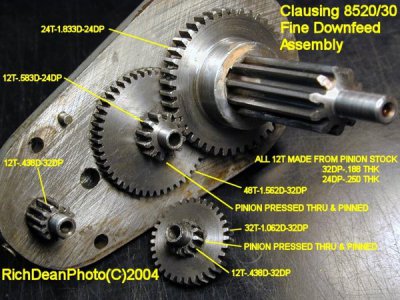

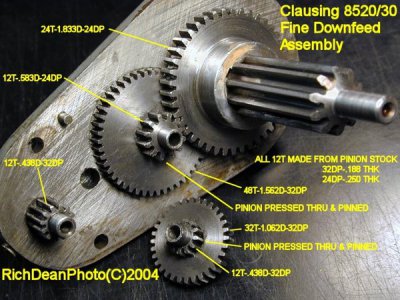

When I purchased my mill the gears seemed a little crunchy. It turned out that they were just dirty with dried grease. Here are some photos I found on the net that show the gear placements.

One owner found one of the gears in his mill was marked Boston Gear S-3232.

Their online catalog shows this to be a 32 DP 14.5 degree PA 32 tooth

The last pinion that drives the last gear that slides on the spline is 24 DP instead of 32 DP.

It turns out that the small spur gear portion of the 8520 compound gear (Clausing part 990-065 – cost $66) is a close match to McMaster-Carr part no. 6325 K31. Cost $7.79. A bit of cutting to get the hub thickness down to 1/4 inch, some finish sanding and reassembly using 1/4″ dia. cold rolled stock as a shaft and a broken length of 1/16″ drill bit as a pin to lock the two gears – and everything works. Whole job took about an hour and a half.

When I purchased my mill the gears seemed a little crunchy. It turned out that they were just dirty with dried grease. Here are some photos I found on the net that show the gear placements.