-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clausing/Colchester 11" (Colchester Bantam 2000)

- Thread starter TAWP Tool

- Start date

- Joined

- Oct 30, 2012

- Messages

- 960

Gregor, it sounds like your tailstock could be slightly offset.

After I shot this video I re-checked sweeping the inside of the MT on the barrel vs the OD. This is my rough hary eyeball method of checking.

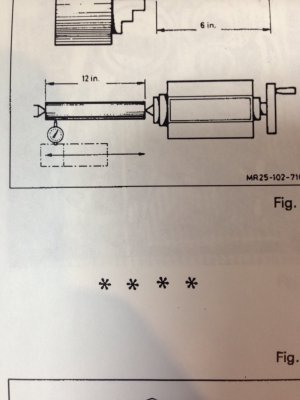

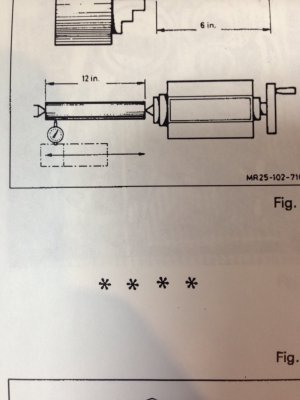

I believe the "real" way to check is traversing with an indicator along a ground bar mounted between centers. If you are turning unwanted tapers when only holding by the chuck then I think the issue is headstock alignment to the bed. Thats a whole nuther can of worms.

After I shot this video I re-checked sweeping the inside of the MT on the barrel vs the OD. This is my rough hary eyeball method of checking.

I believe the "real" way to check is traversing with an indicator along a ground bar mounted between centers. If you are turning unwanted tapers when only holding by the chuck then I think the issue is headstock alignment to the bed. Thats a whole nuther can of worms.

Last edited:

- Joined

- Dec 25, 2011

- Messages

- 10,503

Turning a taper with the work piece held between centers or with chuck or collet and tailstock center is usually an indication of tailstock back set error. Turning a taper with work piece held in chuck or collet may be an indication of a twisted bed or a worn bed.

- Joined

- Dec 25, 2011

- Messages

- 10,503

Yes. However, unless it has had a bad crash or been dropped on the headstock, I would guess it is the least likely as headstocks are generally a tight fit between the ways and if there is an alignment problem, it would have almost had to have been that way since new.

Yes, it was the tailstock that was out of alignment. I managed to adjust it so that the error over 11" is just under .001" which I don't know if I want to try to spend the time to try to improve. I don't know if I was doing it wrong to start but I was turning in the screw on the back side of the tailstock (loosening the one on the front) and the taper got worse so I went backwards to what I thought was the right way to adjust it and screwed in the adjustment screw on the front side and the taper went away and I got it to be basically on. Perhaps you guys are more patient than I am or more particular but I can't see trying to improve on .001" over 11".

Thanks for the advice - it's good know I could turn an axle now if need be.

Gregor

Thanks for the advice - it's good know I could turn an axle now if need be.

Gregor

Gregor,

I would check your tail stock alignment. It is probably adjusted a bit off toward the chip pan. You should be able to adjust it by doing that same cut you are doing or use a test bar between centers.

Colin

- Joined

- Dec 25, 2011

- Messages

- 10,503

Gregor,

0.001" per foot is pretty good. If it is good enough for the parts that you want to make with it, I wouldn't fiddle with it any more.

I took "tighter near the headstock" to mean larger. Which meant that the tailstock was too far forward (toward the operator). I wasn't sure what Colin meant by "off toward the chip pan". My chip pan is symmetrical. But in any case, you figured out which direction to move the tailstock.

0.001" per foot is pretty good. If it is good enough for the parts that you want to make with it, I wouldn't fiddle with it any more.

I took "tighter near the headstock" to mean larger. Which meant that the tailstock was too far forward (toward the operator). I wasn't sure what Colin meant by "off toward the chip pan". My chip pan is symmetrical. But in any case, you figured out which direction to move the tailstock.

- Joined

- Nov 18, 2013

- Messages

- 86

I've always known them as a fixed or floating steady either way you would knowThe common name for the rest that is attached to and moves with the carriage is Follow Rest or Follower Rest.

I've always known them as a fixed steady and a travelling steady! As long as they do the job!I've always known them as a fixed or floating steady either way you would know

Hi Guys

Sorry to jump in here, just bought one these beauties in a sorry state. Being delivered tomorrow, Don`t suppose anyone has a manual in PDF they would be willing to mail me or post a link to. attached a picture of it in its present location, as you can see it needs a lot of attention.

cheers

Sorry just found the manual in the downloads section cheers

Sorry to jump in here, just bought one these beauties in a sorry state. Being delivered tomorrow, Don`t suppose anyone has a manual in PDF they would be willing to mail me or post a link to. attached a picture of it in its present location, as you can see it needs a lot of attention.

cheers

Sorry just found the manual in the downloads section cheers

Last edited: