- Joined

- Dec 6, 2012

- Messages

- 2,677

Went back today as instructed.

I showed pics of how I've cleaned her up (dust & grease), how I moved her, and how I'm leveling her.

Evidently they deemed me worthy to look through the shelves with misc stuff collected over multiple decades. As I was leaving I was told how comforted they were in knowing that I would be taking good care of her.

I was ultimately sent me home with a dog plate, 2 carriage micrometer stops (one for the Colchester and one for my large BoyeEmmes), a Hardinge 5c spindle nose collet chuck, a MT live center and a MT jacobs chuck to fit.

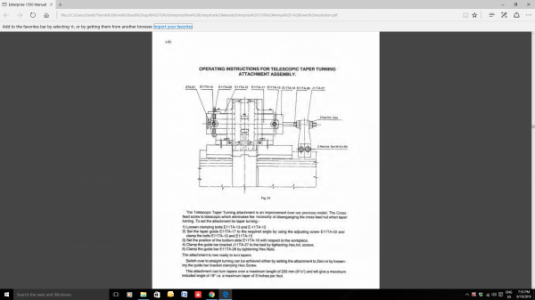

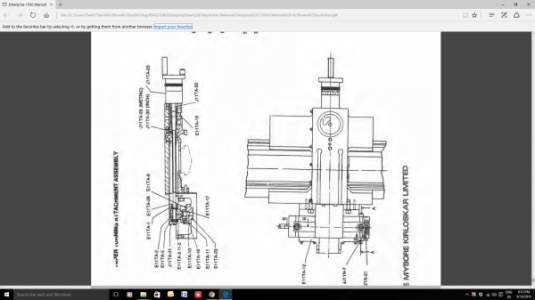

And one of our members forwarded some digital manuals. That's tonights reading.

I've really been blessed this week!

I'm hoping to find a HM who might make me an offer on one of the lathes which I have posted in Classifieds so that I can pass on the blessings.

Daryl

MN

I showed pics of how I've cleaned her up (dust & grease), how I moved her, and how I'm leveling her.

Evidently they deemed me worthy to look through the shelves with misc stuff collected over multiple decades. As I was leaving I was told how comforted they were in knowing that I would be taking good care of her.

I was ultimately sent me home with a dog plate, 2 carriage micrometer stops (one for the Colchester and one for my large BoyeEmmes), a Hardinge 5c spindle nose collet chuck, a MT live center and a MT jacobs chuck to fit.

And one of our members forwarded some digital manuals. That's tonights reading.

I've really been blessed this week!

I'm hoping to find a HM who might make me an offer on one of the lathes which I have posted in Classifieds so that I can pass on the blessings.

Daryl

MN