- Joined

- Feb 28, 2019

- Messages

- 499

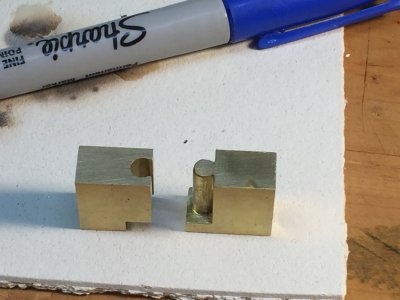

I'm looking for a simple, common (cheap) cleaning protocol prior to silver soldering small brass parts (think just a few steps up from jewelry making). Ideally it would be just a bath and a rinse prior to fluxing and soldering.

I need to remove finger prints and oils from machining processes.

I've tried soap and water, DNA, windex with varying degrees of success.

The parts can be somewhat complicated and already have a pretty precise fit and are small - hence I don't want to do an abrasive cleaning.

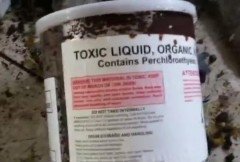

Seems like I just need to find the right grease/oil dissolving solution.

Thoughts and suggestions?

I need to remove finger prints and oils from machining processes.

I've tried soap and water, DNA, windex with varying degrees of success.

The parts can be somewhat complicated and already have a pretty precise fit and are small - hence I don't want to do an abrasive cleaning.

Seems like I just need to find the right grease/oil dissolving solution.

Thoughts and suggestions?