-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleaning up a tired old carbide grinder

- Thread starter WobblyHand

- Start date

- Joined

- Dec 18, 2019

- Messages

- 6,438

Thanks for posting that! Interesting idea. Relatively simple. Does the diamond holder include the screwdriver handle? I found some 6" long diamond points, which would give me some additional leeway in a design.I’ve been meaning to get a picture for this thread. This is the dressing tool that came with my Rockwell carbide grinder:

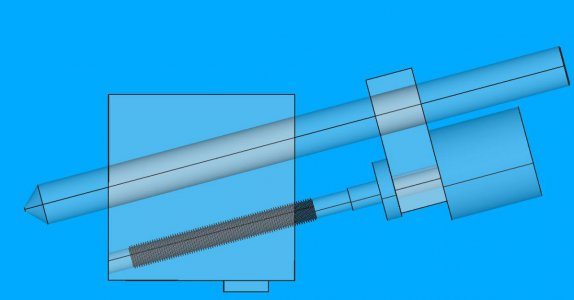

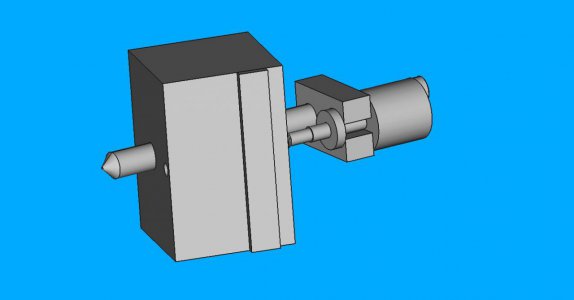

View attachment 389761

View attachment 389762

It’s nothing too complicated but it seems to work well with the same functionality you have been discussing, albeit using a plain screw for adjustment.

Thanks for posting that! Interesting idea. Relatively simple. Does the diamond holder include the screwdriver handle? I found some 6" long diamond points, which would give me some additional leeway in a design.

Yes the handle is integral to the diamond tool. It’s not at all necessary though, as the adjuster saddle clamps to the diamond-tool shaft.

- Joined

- Dec 18, 2019

- Messages

- 6,438

@jwmelvin finally getting back to this. Is the adjuster screw assembly one piece? Or, is the adjuster knob screwed in and held somehow? It almost looks like it could be a single piece. I just acquired a 6" long 7/16" diameter diamond tool. Guessing from the dimensions, the holder is roughly 3"Wx2"Lx2"H? This could be my first FreeCAD project. It is simpler than what I was thinking, but that's good for a first CAD project.

- Joined

- Mar 26, 2018

- Messages

- 8,407

They are very durable. You just need to dress them.True for expensive wheels. A true blue US/EU CBN wheel is an expensive accoutrement. Stefan Goetteswinter said in one of his vids that he has a chinese CBN wheel (Shars type) and abuses it heavily with carbide. I thought there was something to it, so I started grinding anything and everything on one of my chinese CBN wheels. A couple of years and some hard floggings later, the wheel is still good and my stuff is easy to keep sharp. Carbide does grind on these wheels, and they take it. Maybe not as efficient as a true (expensive) carbide grinding wheel, but plenty sufficient for my home shop needs.

That’s the fun part

@jwmelvin finally getting back to this. Is the adjuster screw assembly one piece? Or, is the adjuster knob screwed in and held somehow? It almost looks like it could be a single piece. I just acquired a 6" long 7/16" diameter diamond tool. Guessing from the dimensions, the holder is roughly 3"Wx2"Lx2"H? This could be my first FreeCAD project. It is simpler than what I was thinking, but that's good for a first CAD project.

I remember it being just a single piece, with a necked section to engage the yoke. I can go look closer and measure for you in a minute.

Guessing from the dimensions, the holder is roughly 3"Wx2"Lx2"H?

Sorry, forgot to do this. You were right. About 3.25" W x 2.5" L x 1.5" H. None of that seems critical. The screw is a single piece with a narrow waist that engages the yoke. Happy to provide any additional details that may help.I remember it being just a single piece, with a necked section to engage the yoke. I can go look closer and measure for you in a minute.

- Joined

- Mar 26, 2018

- Messages

- 8,407

Wobbly,

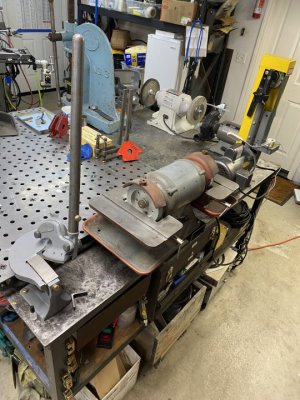

You motivated me to pull out my Baldor grinder. (the drip pans are on the shelf, this thing is heavy as it is)

I was reminded how quiet and smooth this runs.

I had a knock off that I lost in the fire. I had to go through it like you are.

These can be very handy.

I haven't used it lately because I have my slow speed 8" diamond lapping machine and a D-bit -U2 grinder.

After using this yesterday, I am reminded how much I like it. I'll need to find a spot for it.

Found one.

You motivated me to pull out my Baldor grinder. (the drip pans are on the shelf, this thing is heavy as it is)

I was reminded how quiet and smooth this runs.

I had a knock off that I lost in the fire. I had to go through it like you are.

These can be very handy.

I haven't used it lately because I have my slow speed 8" diamond lapping machine and a D-bit -U2 grinder.

After using this yesterday, I am reminded how much I like it. I'll need to find a spot for it.

Found one.

Attachments

Last edited:

- Joined

- Dec 18, 2019

- Messages

- 6,438

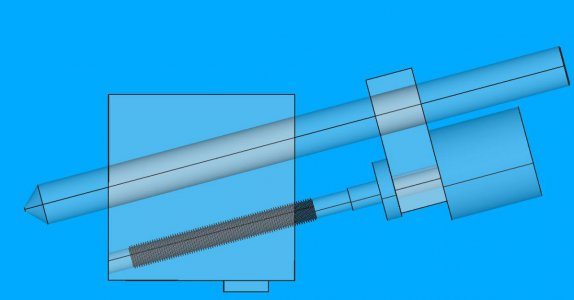

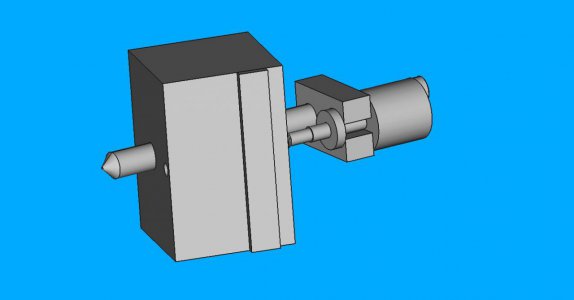

Lest, you all think I'm a slacker, I've been busy at this. I have ordered some cast iron for the diamond dresser holder tool. Should be here tomorrow. Here's my initial stab at a design. Had to learn FreeCAD to make this drawing which took me about 3 weeks. I found it hard, but plodded along at it. Just learned how to do an assembly today. Need to finesse the main block, it's still a huge 2x2x3 rectangular block. However, it should be nice and heavy, which is a good thing. Design uses 1/4-40 threads, which I hope I can tap into grey cast iron. Got a bit more work to do on this. Design idea based on the photo courtesy of @jwmelvin.