-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Oct 24, 2013

- Messages

- 481

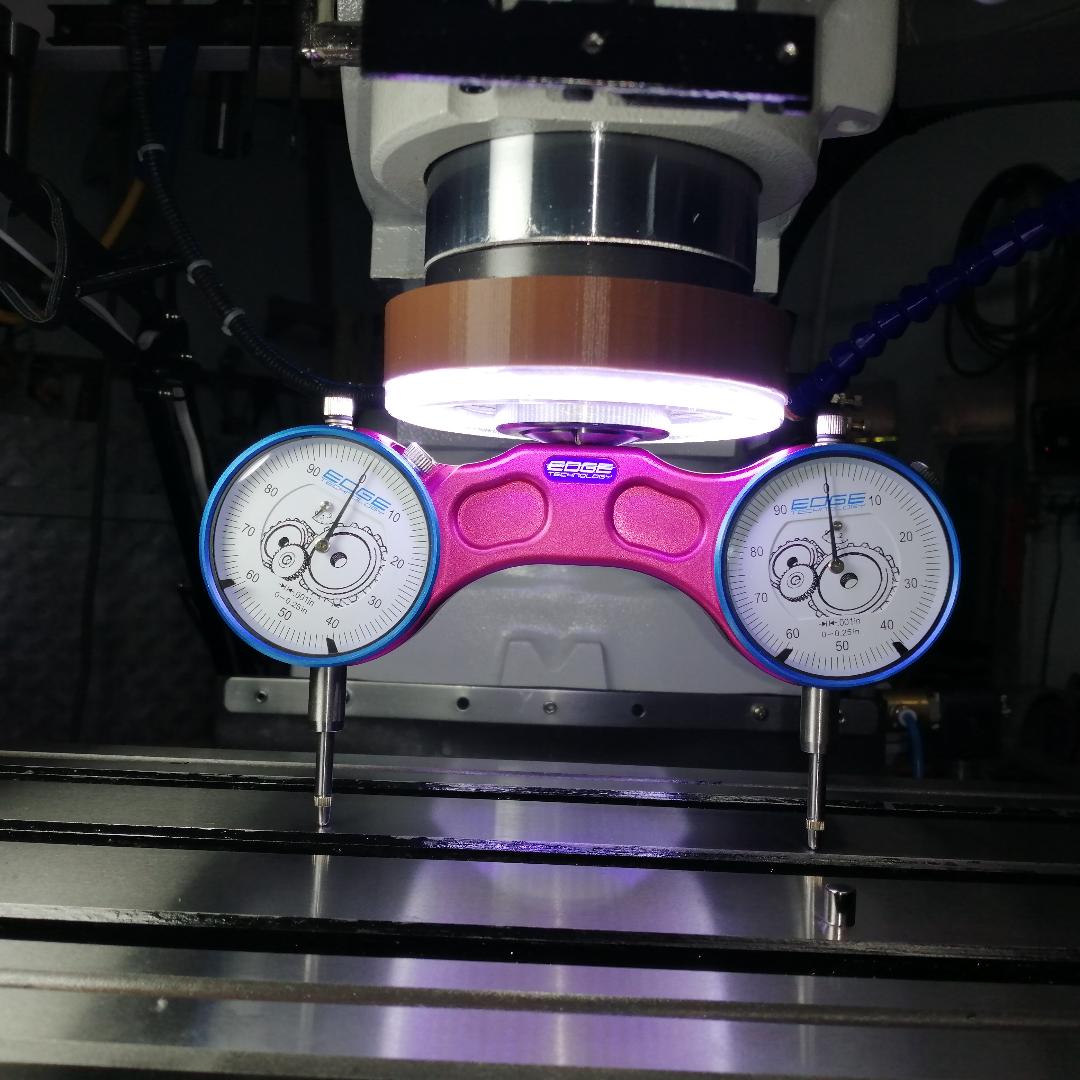

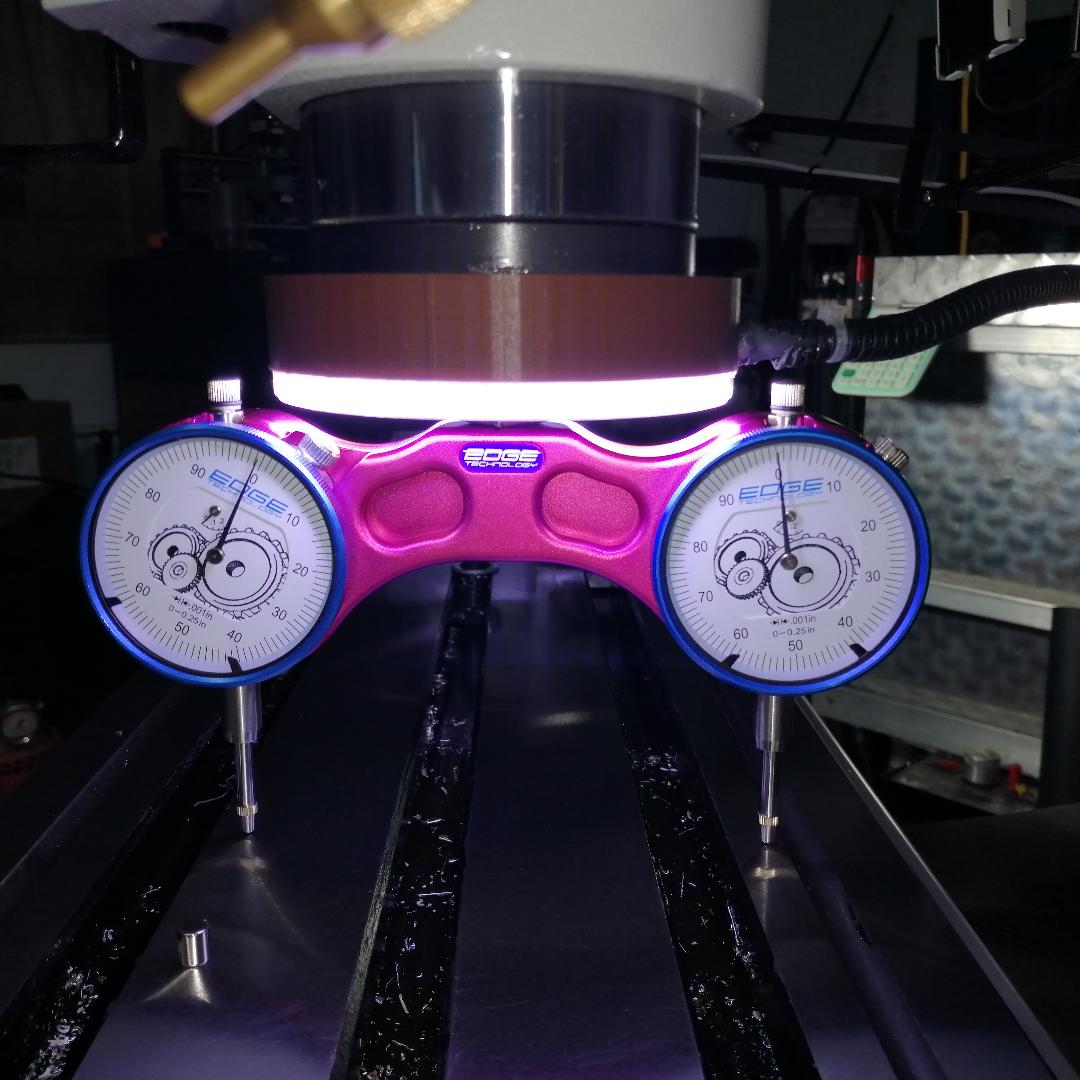

Now that the mill has been in use quite a bit and everything should have settled-in, I decided to check the table tram and tweak it as necessary.

Well, no tweaking necessary, both axes dead-nuts, spot on!

I could not be happier with this machine!

Well, no tweaking necessary, both axes dead-nuts, spot on!

I could not be happier with this machine!

- Joined

- Nov 23, 2020

- Messages

- 786

Looks like a cool tool, but how is it calibrated?

Edit - I am guessing flip 180 and look for the same reading to calibrate?

Edit - I am guessing flip 180 and look for the same reading to calibrate?

- Joined

- Oct 24, 2013

- Messages

- 481

So, Here's the first component failure.

I'm in the middle of a commercial job and I could not get the R8 Collet / tool to eject. Took off the Maxi Torque Power Drawbar and found the threads have failed. Manufacturer suggests running at 90psi and adjust the strength from there. I found that to be a bit aggressive and from day one been running it at 80psi.

Sending Precision Matthews an email now outlining this issue. Hope we can get this corrected soon.

EDIT:

Looks like it frigged-up the internal threads in my Accusize 3'' Carbide R8 Indexable End Mill too! .....arrrrgh, CRAP!! Will try chasing it tomorrow with a 7/16 - 20 tap.

Will try chasing it tomorrow with a 7/16 - 20 tap.

Just chased the threads in the R8 face-mill with the 7/16 - 20 tap, seems like I got lucky this time!

I'm in the middle of a commercial job and I could not get the R8 Collet / tool to eject. Took off the Maxi Torque Power Drawbar and found the threads have failed. Manufacturer suggests running at 90psi and adjust the strength from there. I found that to be a bit aggressive and from day one been running it at 80psi.

Sending Precision Matthews an email now outlining this issue. Hope we can get this corrected soon.

EDIT:

Looks like it frigged-up the internal threads in my Accusize 3'' Carbide R8 Indexable End Mill too! .....arrrrgh, CRAP!!

Just chased the threads in the R8 face-mill with the 7/16 - 20 tap, seems like I got lucky this time!

Last edited:

- Joined

- Oct 24, 2013

- Messages

- 481

Yes, they even give you a little magnet that acts as a calibration post to do just that.Looks like a cool tool, but how is it calibrated?

Edit - I am guessing flip 180 and look for the same reading to calibrate?

- Joined

- Oct 7, 2020

- Messages

- 2,108

Oh Man, That's a bummer about the power draw bar and your Indexable End Mill. I hope PM helps you out.

On another note where did you get your spindle light?

On another note where did you get your spindle light?

- Joined

- Oct 24, 2013

- Messages

- 481

The spindle light / tach hall sensor is my 3D printed version, based on drawings by David Best. The Halo LED light ring itself is available on ebay.

2X COB Halo Ring 100mm Angel Eyes White Light LED For Headlight Projector Lens | eBay

Find many great new & used options and get the best deals for 2X COB Halo Ring 100mm Angel Eyes White Light LED For Headlight Projector Lens at the best online prices at eBay! Free shipping for many products!

www.ebay.com

- Joined

- Oct 24, 2013

- Messages

- 481

I just had a nice conversation with Mike at the Tech Dept over at PM, they're sending me a new draw bar, as they may have in stock. He seems to think it was over torqued, I don't see how, cause the mfg suggests running at 90psi and I been running at 80psi from day one. Let's see how it goes.

What pressures are you guys running at??? ......maybe I should go down to 70 or 75?

EDIT

Replacement Drawbar on it's way via USPS.

What pressures are you guys running at??? ......maybe I should go down to 70 or 75?

EDIT

Replacement Drawbar on it's way via USPS.

Last edited:

- Joined

- Nov 23, 2020

- Messages

- 786

How long are you holding the button to tighten down? .5 to 1.5 Secs is what the manual suggests.I just had a nice conversation with Mike at the Tech Dept over at PM, they're sending me a new draw bar, as they may have in stock. He seems to think it was over torqued, I don't see how, cause the mfg suggests running at 90psi and I been running at 80psi from day one. Let's see how it goes.

What pressures are you guys running at??? ......maybe I should go down to 70 or 75?

- Joined

- Oct 24, 2013

- Messages

- 481

No more than 1.5 sec max. just a quick Burrrp !How long are you holding the button to tighten down? .5 to 1.5 Secs is what the manual suggests.