- Joined

- Oct 24, 2013

- Messages

- 481

Just used my "Jog Speed" to power-tap a bunch of M6 holes ........how sweet it is!

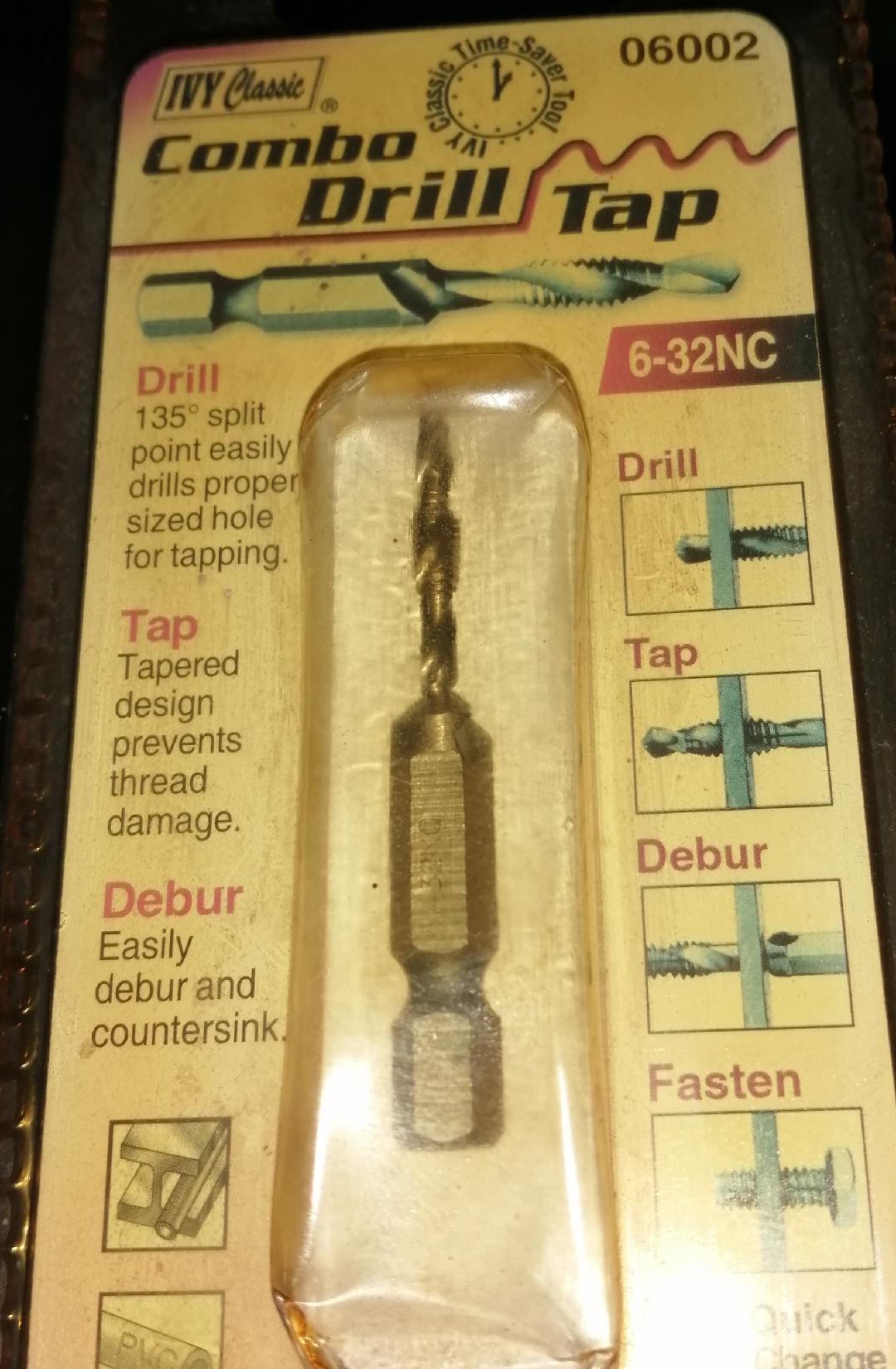

I'm going to experiment with a few of these too, although I believe they're generally frowned upon by machinists

EDIT: I can certainly make use of these for some applications. I used one today to drill and tap some holes in 3/8" plate with the mill, worked just great, as I said, some applications.

I'm going to experiment with a few of these too, although I believe they're generally frowned upon by machinists

EDIT: I can certainly make use of these for some applications. I used one today to drill and tap some holes in 3/8" plate with the mill, worked just great, as I said, some applications.

Last edited: