- Joined

- Nov 24, 2014

- Messages

- 3,152

@JimDawson

LOL I've got to pile on.

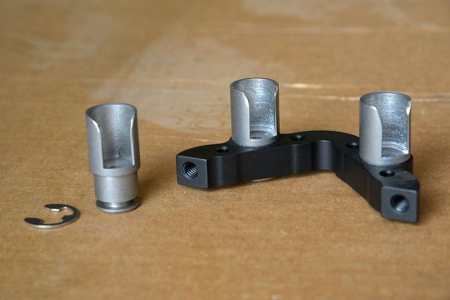

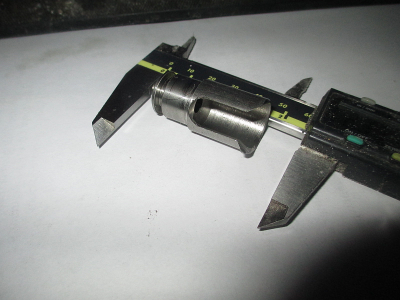

I'm away from home and have limited tools available. I have some round parts with 5/16 hex center hole. I wanted to use a cordless tool as a lathe to spin the part so I could deburr and cleanup an OD thread. Great, all I need is a 5/16 hex insert bit or power bit. I would have sworn I had one (or more) in my kit. No such luck. ACE Hardware doesn't stock it. Even struck out at a used tool shop. I went to two brick and mortar stores (in a highly populated area of Los Angeles, CA) wasting my time and probably $10 on fuel.

On Amazon, an industrial supplier in Houston, TX had exactly what I wanted (Bondhus 3" long power bit, USA made) for $3.09 total delivered. It was sent FedEx, in a 8" x 8" x 7" cardboard box and arrived in 2 or 3 days. They must have lost $$ on this one. McMaster has a 2" long option for $11.53+tax+S&H.

LOL I've got to pile on.

I'm away from home and have limited tools available. I have some round parts with 5/16 hex center hole. I wanted to use a cordless tool as a lathe to spin the part so I could deburr and cleanup an OD thread. Great, all I need is a 5/16 hex insert bit or power bit. I would have sworn I had one (or more) in my kit. No such luck. ACE Hardware doesn't stock it. Even struck out at a used tool shop. I went to two brick and mortar stores (in a highly populated area of Los Angeles, CA) wasting my time and probably $10 on fuel.

On Amazon, an industrial supplier in Houston, TX had exactly what I wanted (Bondhus 3" long power bit, USA made) for $3.09 total delivered. It was sent FedEx, in a 8" x 8" x 7" cardboard box and arrived in 2 or 3 days. They must have lost $$ on this one. McMaster has a 2" long option for $11.53+tax+S&H.