- Joined

- Nov 29, 2017

- Messages

- 13

i have been a manual lathe guy for many years but i am now jumping into the cnc world. i purchased a used haas tl-1 and am learning slowly.

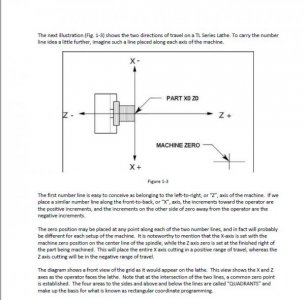

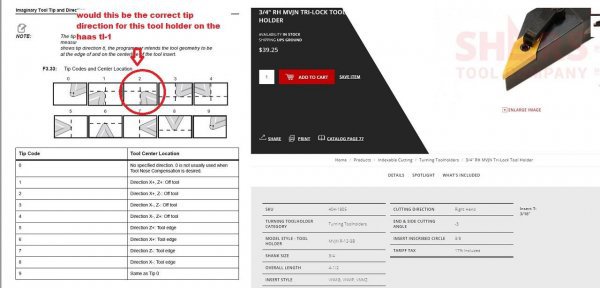

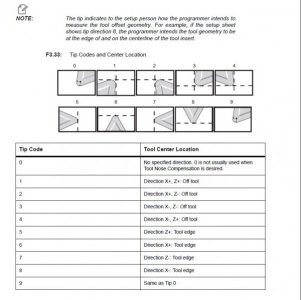

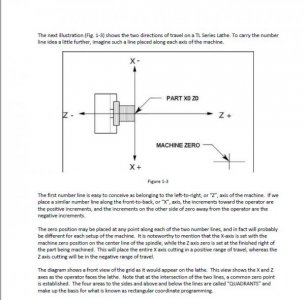

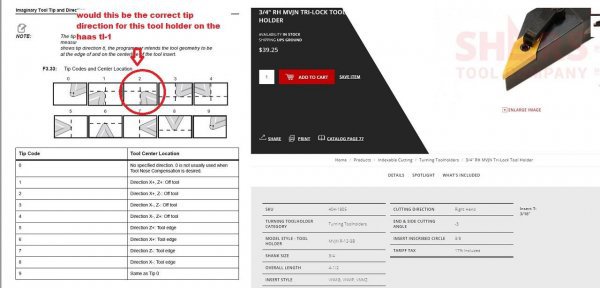

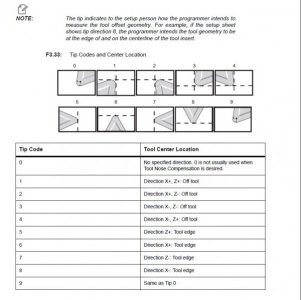

i am having a hard time understanding how to set up my tools for the tool tip orientation for tool tip compensation. i look at the charts and think one thing but then see others say something else. can some one help explain it? here are some pics of what i am talking about. i am using a vnmg right hand tool for outside turning so i look at the first pic and my tip looks like #2 but i have read that possible it is put in the lathe as #3. but then i look at the other 2 pics which is how i was thinking in the first place that the tip is sitting in the x+/z+ position so it would be #4

am i making it too complicated? just lost and hoping someone can help.

i am having a hard time understanding how to set up my tools for the tool tip orientation for tool tip compensation. i look at the charts and think one thing but then see others say something else. can some one help explain it? here are some pics of what i am talking about. i am using a vnmg right hand tool for outside turning so i look at the first pic and my tip looks like #2 but i have read that possible it is put in the lathe as #3. but then i look at the other 2 pics which is how i was thinking in the first place that the tip is sitting in the x+/z+ position so it would be #4

am i making it too complicated? just lost and hoping someone can help.