-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC Plasma Cutting When You Have No Space

- Thread starter Tmate

- Start date

- Joined

- Jul 15, 2020

- Messages

- 421

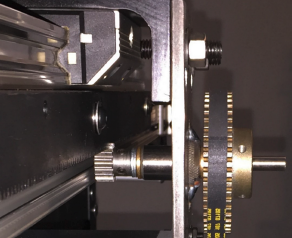

The 8020 extrusions are Part #2020 which has a 2" x 2" cross section.

For years, 8020 would not sell directly to the consumer, but rather through a network of fluid/hydraulics distributors. When Torchmate was using their extrusions, we had to go through a distributor in North Carolina, even when we were buying more of their stuff than most of their distributors. A number of years later, they started selling on eBay. Now, they appear to be selling direct via their web site. There are still a number of other sources on eBay selling either 8020 or look alike products.

For years, 8020 would not sell directly to the consumer, but rather through a network of fluid/hydraulics distributors. When Torchmate was using their extrusions, we had to go through a distributor in North Carolina, even when we were buying more of their stuff than most of their distributors. A number of years later, they started selling on eBay. Now, they appear to be selling direct via their web site. There are still a number of other sources on eBay selling either 8020 or look alike products.

- Joined

- Jul 15, 2020

- Messages

- 421

- Joined

- Feb 16, 2021

- Messages

- 35

I am very tight for space as well and was thinking of doing a 2x4 table with guides or supports so I can still feed a 4x8 sheet into it without prior trimming.

I just wasn't sure if it was worth the investment for such a small capability. Good to know that height control may not be as necessary as everyone says it is.

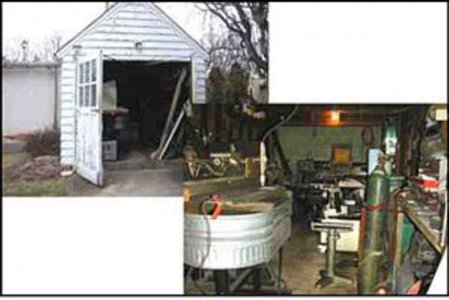

I also like that you used a basin rather than a water table. I like the idea of folding or collapsing legs and the ability to stand it on end for storage so a water table makes that much more difficult.

I just wasn't sure if it was worth the investment for such a small capability. Good to know that height control may not be as necessary as everyone says it is.

I also like that you used a basin rather than a water table. I like the idea of folding or collapsing legs and the ability to stand it on end for storage so a water table makes that much more difficult.

- Joined

- Feb 16, 2021

- Messages

- 35

I'm not sure how my neighbors would react to me doing plasma cutting in my driveway so I have to plan on it being in my garage.

There's a good chance it's just not feasible at this location and the dream of CNC plasma will need to wait until I get a proper shop again.

There's a good chance it's just not feasible at this location and the dream of CNC plasma will need to wait until I get a proper shop again.

- Joined

- Jul 15, 2020

- Messages

- 421

I'm not sure how my neighbors would react to me doing plasma cutting in my driveway so I have to plan on it being in my garage.

There's a good chance it's just not feasible at this location and the dream of CNC plasma will need to wait until I get a proper shop again.

I used to do my cutting in my garage in another house. I put the table just inside the garage door with a big fan blowing as much as possible out the door. My garage sat to the rear of my house, but was still clearly visible from the street. Neighbors saw some flashes of light, but no one ever complained.