- Joined

- Jul 15, 2020

- Messages

- 421

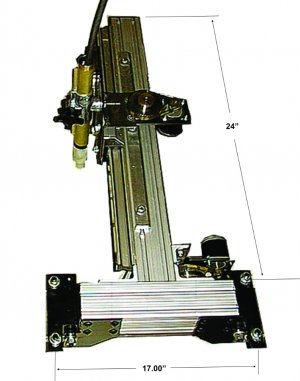

Sorry - back on topic, 24" (i.e. 600-610) cut area will be just fine. I am therefore roughly planning on X axis rails of about 1000mm (39.4") and a Y axis rail of about 750-800mm (29.5" to 31.5"). So if you know what your wheel spacing was (roughly) that would be rather useful. 10", 12" or something else?

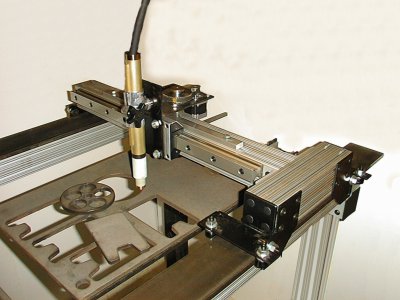

Hopefully these photos will be of help. Note that the pictured machine used 3" x 3" extrusions and a 35mm linear rail. While both of these were overkill, the assembly was a bit stiffer than my later 2x2. Also, the motor and X axis gear rack were mounted on the inside of the short extrusion, slightly reducing the need for a wider bearing spacing.