I have a 1987.5 Enco round column mill, according to the cover plate that does not look quite original, that acquired about 10-12 years ago. Not quite sure on the exact model. I have considered trying to sell it since I have a Russian made Deckel clone I use more often because it has built in power feeds. The RF 30 has more range and I am not short of room currently, so it has been kept. Anyhow, I thought turning it into CNC was a $2-3K binge, so I never really thought seriously about it. Then I saw a thread about a cheap(ish) kit to make it happen and I did the math and though for sub $1k I could do it. So I jumped off the deep end and bought some stuff. THEN I started taking apart my mill to prep and see the condition of things. Well, I was bassackwards in my process. I really should have done a better job figuring out the condition of my machine and the layout prior to purchasing stuff. I am committed now, I have the steppers, and the driver is in the mail. Now I have to figure out what to do.

It was after I bought stuff that I realized my machine with factory power on the z-axis is less than common. I am not sure what the drive mechanism is for a non-power downfeed machine, but I have 2 points of slop in my z-axis. The worm gear from the front and the interface with the quill. Between the two, I am not certain that any real degree of accuracy can be achieved, even with the shock conversion that seems to be popular to reduce the z-axis backlash.

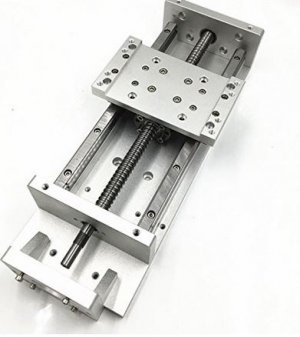

My x-axis had a bunch of backlash, like 50 thou. Since I had always used it manually, and usually not to do anything but hog material, it had never been an issue. After I bought stuff and inspected things for real, it was apparent that slop was only in the middle 6-8in of the table. The ends are really tight. This seems like a bad start for CNC so I think I need to swap to ball screws from the get go. Project creep.

I have disassembled things further than I am really comfortable with and am plunging into new territory. As of today I have made a real mess of things and hopefully can put humpty dumpty back together again.

This is where I am currently. Seems quite the mess I have gotten myself into.

mess I ahve

mess I ahve

It was after I bought stuff that I realized my machine with factory power on the z-axis is less than common. I am not sure what the drive mechanism is for a non-power downfeed machine, but I have 2 points of slop in my z-axis. The worm gear from the front and the interface with the quill. Between the two, I am not certain that any real degree of accuracy can be achieved, even with the shock conversion that seems to be popular to reduce the z-axis backlash.

My x-axis had a bunch of backlash, like 50 thou. Since I had always used it manually, and usually not to do anything but hog material, it had never been an issue. After I bought stuff and inspected things for real, it was apparent that slop was only in the middle 6-8in of the table. The ends are really tight. This seems like a bad start for CNC so I think I need to swap to ball screws from the get go. Project creep.

I have disassembled things further than I am really comfortable with and am plunging into new territory. As of today I have made a real mess of things and hopefully can put humpty dumpty back together again.

This is where I am currently. Seems quite the mess I have gotten myself into.

mess I ahve

mess I ahve

Last edited: