Hi all,

Happy New year to you all.

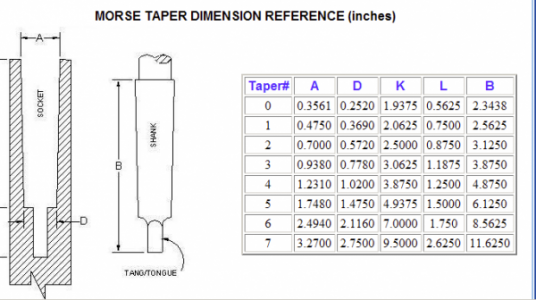

I have the above lathe, square head and have a question regarding the spindle nose. I would like to run some parts between centers, but my lathe didn't come with the adapter to fit the spindle bore to take a MT3 dead center.

So is the adapter screwed onto the LO spindle or just fits in the spindle nose. Looks like it has a small taper but I maybe wrong.

What material would you suggest I use to make this adapter, EN8,9 or 19?

Regards,

Greg

Happy New year to you all.

I have the above lathe, square head and have a question regarding the spindle nose. I would like to run some parts between centers, but my lathe didn't come with the adapter to fit the spindle bore to take a MT3 dead center.

So is the adapter screwed onto the LO spindle or just fits in the spindle nose. Looks like it has a small taper but I maybe wrong.

What material would you suggest I use to make this adapter, EN8,9 or 19?

Regards,

Greg