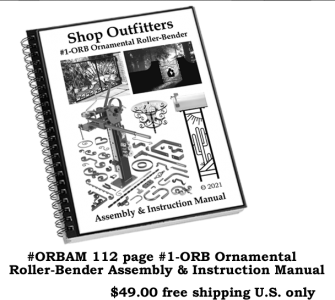

Mine came with a very good manual, without which I'd have trouble with some of the setups. I still reference it routinely - there's always a relevant example. YouTube is probably the best source of info if you don't have a good manual.It's always a huge mental struggle for me to figure out how to set up a particular bend. Do you guys just walk up and presto, there's your piece?

The good part is it's really easy to make custom dies.

GsT