-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Compressed air distribution in your shop?

- Thread starter Janderso

- Start date

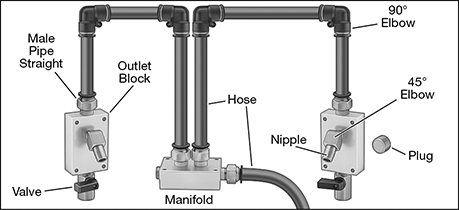

I have not. I used the ¾" RapidAir kit and have been very happy with it. https://www.northerntool.com/shop/tools/product_200484023_200484023

Looks like Rapid Air. Lots of people use them and like them. I worked at an auto repair shop which just used schedule 40 pvc. Personally I would prefer schedule 80 since it’s much stronger. Schedule 40 would occasionally blow at odd places anytime.

I was amazed how well the schedule 40 actually worked. Had a 2-stage compressor set at 155 psi. 4 full time mechanics.

I was amazed how well the schedule 40 actually worked. Had a 2-stage compressor set at 155 psi. 4 full time mechanics.

- Joined

- Feb 8, 2014

- Messages

- 11,144

You can get the same thing at Automation Direct for about 1/5 the cost/item, and free 2 day shipping on orders over $49. https://www.automationdirect.com/adc/shopping/catalog/pneumatic_components

I have been using these products for years and have about 1/2 my shop plumbed with these products.

I have been using these products for years and have about 1/2 my shop plumbed with these products.

Copper is the right stuff. Go to almost any older auto dealership and it’s copper. But copper is pretty expensive...especially the thicker stuff which is what you want. Believe it or not...3/4” PVC 40 has a working pressure of 200 at 140 degrees. Home Depot site shows the specs.

But...it used to pop every now and then. The upside of pvc is it doesn’t form condensation. And it’s dirt cheap and easy as hell to install.

also...most pvc breaks down if exposed to sunlight. Recommended to paint it if outside.

But...it used to pop every now and then. The upside of pvc is it doesn’t form condensation. And it’s dirt cheap and easy as hell to install.

also...most pvc breaks down if exposed to sunlight. Recommended to paint it if outside.

- Joined

- Mar 14, 2013

- Messages

- 443

Can't go wrong with copper, but it's expensive. When I plumbed my shop for air I used polyethylene tubing (rated 190 psi in the 1/2" OD size) and nylon compression tees and elbows (rated 200 psi). It was the cheapest stuff McMaster had that was rated for the pressure (I run my compressor at 120psi). At the ends I clamped a 6" galvanized pipe nipple to the shop rafters with a quick disconnect coupling on the bottom and the compression fitting for the tubing on the top.

PVC pipe is a bad idea for an air system... while it's rated for the pressure, it's brittle so it fatigues if the pressure fluctuates a lot, i.e. if you don't leave the system pressurized so it goes to zero often.

PVC pipe is a bad idea for an air system... while it's rated for the pressure, it's brittle so it fatigues if the pressure fluctuates a lot, i.e. if you don't leave the system pressurized so it goes to zero often.

- Joined

- Dec 21, 2013

- Messages

- 798

I think the only difference between the kits is the McMaster is 1/2" vs. 3/4"

Any advantage to the 3/4" ?

The 1/2" is rated at 150 psi.

The advantage is more volume of flow, some tools use more cfm than others

so the efficiency of 3/4" is greater on high consumption tools ..............