- Joined

- Sep 20, 2019

- Messages

- 1,331

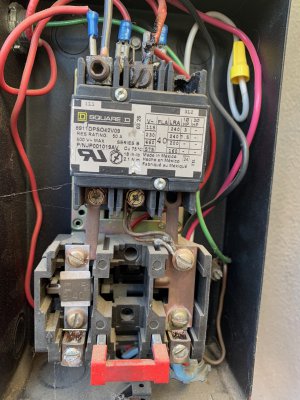

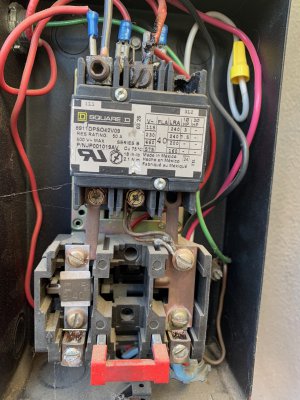

I have a Husky Pro, 7.5 HP, 230V 1PH, 80 gallon air compressor. I purchased it used a couple of years ago. It had meltdown before I bought it, but they fixed it and I've had no issues until tonight. One of the feeds melted down, and what brought it to my attention was that it sounded like the air line at the compressor blew because it was exhausting air at a furious rate. I couldn't find a blown line, but noticed one of the 115v feeds lines was smoking at the connector. I figure it's time for a new one but am concerned why it didn't trip something to interrupt it. I shopped replacements and found prices range from about $170 hundreds more. Mine is a Square D 8911DPS042V09. In the photo, to right, you can see the melting damage from the previous failure. To the left of it is my meltdown. I appreciate any and all advice. Thanks!