Nice easy fix! The gauge you have now, is it oil filled? If yes, could be an even easier & cheaper fix. Oil filled gauges sometimes need to be vented periodically due to climate changes.

My current air compressor I bought an oil filled gauge for it. Didn't come prefilled so I filled it up with glycerin to the appropriate level & thought nothing of it. Fast forward to 6 or 7 yrs later, I noticed the gauge wasn't reading as high as it should. Noticed it looked overfilled too but I haven't touched it since. My pressure switch is adjustable (high & low cutoff) & that's what I thought to do also. But all the other gauges on my air system all read fine (none of them are oil filled).

Turns out my Wika gauge has a ventable plug. Flipped the lever to vent & then the gauge was reading normal again. Some gauges have a little nipple on the plug that you can cut. Or you can vent by slightly lifting the plug. Only other oil filled gauages I've ever had were for cars, I never knew about venting them.

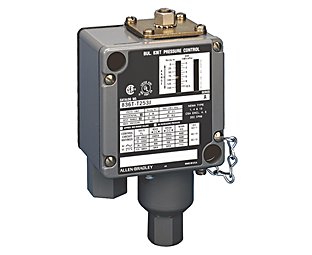

View attachment 450083

The pic I found online where I learned this.

View attachment 450084