- Joined

- Feb 8, 2014

- Messages

- 11,144

I ran into something I don't understand.

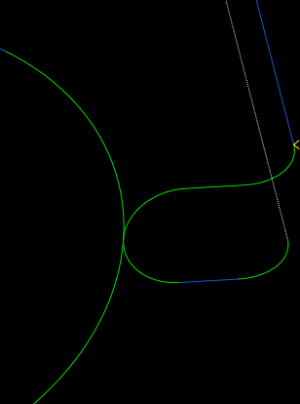

The following code snippet is the lead in for a cut. The lead in is a G18 (XZ plane), with a G3 arc move. A G3 is a counterclockwise arc, but when standing at the front of the machine the toolpath scribes a clockwise arc. CamBam agrees with Fusion on the direction so I assume that the G code is correct and follows standard conventions. When standing in front of the machine the tool path is a reversed ''J'' with the tool starting at the top and following the ''J'' down which looks like a clockwise arc from the operator perspective.

In the XY plane arc direction is as expected when looking down on the part.

N4665 G17 (XY PLANE)

N4670 Z-0.175

N4675 G18 G3 X3.1825 Z-0.2 I-0.025 K0 (CHANGE TO XZ PLANE, AND SCRIBE A COUNTERCLOCKWISE ARC)

N4680 G1 X3.1575 F24

N4685 G17 G3 X3.1325 Y-1.0065 I0 J-0.025 (XY PLANE)

Here is an image of the tool path, Z is towards the top of the screen, X+ is to the right. The little yellow ''< '' is the start point.

Help me get my head around this. I guess the real question is: From the operator perspective is the direction backwards? Should I be looking at this from the machine perspective, in other words standing at the machine column?

.

.

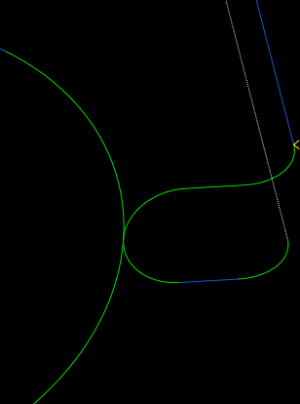

The following code snippet is the lead in for a cut. The lead in is a G18 (XZ plane), with a G3 arc move. A G3 is a counterclockwise arc, but when standing at the front of the machine the toolpath scribes a clockwise arc. CamBam agrees with Fusion on the direction so I assume that the G code is correct and follows standard conventions. When standing in front of the machine the tool path is a reversed ''J'' with the tool starting at the top and following the ''J'' down which looks like a clockwise arc from the operator perspective.

In the XY plane arc direction is as expected when looking down on the part.

N4665 G17 (XY PLANE)

N4670 Z-0.175

N4675 G18 G3 X3.1825 Z-0.2 I-0.025 K0 (CHANGE TO XZ PLANE, AND SCRIBE A COUNTERCLOCKWISE ARC)

N4680 G1 X3.1575 F24

N4685 G17 G3 X3.1325 Y-1.0065 I0 J-0.025 (XY PLANE)

Here is an image of the tool path, Z is towards the top of the screen, X+ is to the right. The little yellow ''< '' is the start point.

Help me get my head around this. I guess the real question is: From the operator perspective is the direction backwards? Should I be looking at this from the machine perspective, in other words standing at the machine column?

.

.