- Joined

- Oct 30, 2012

- Messages

- 960

Guys,

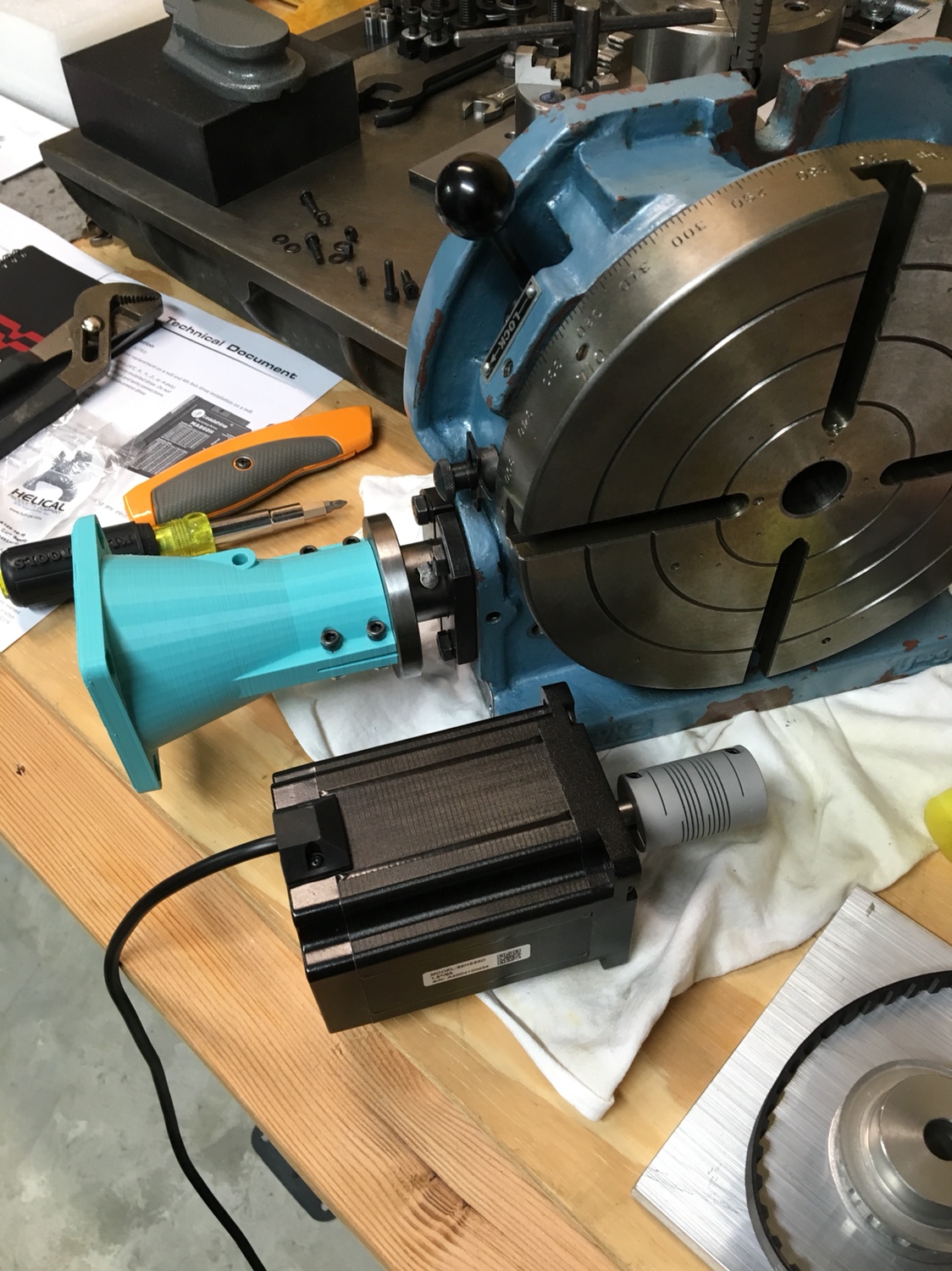

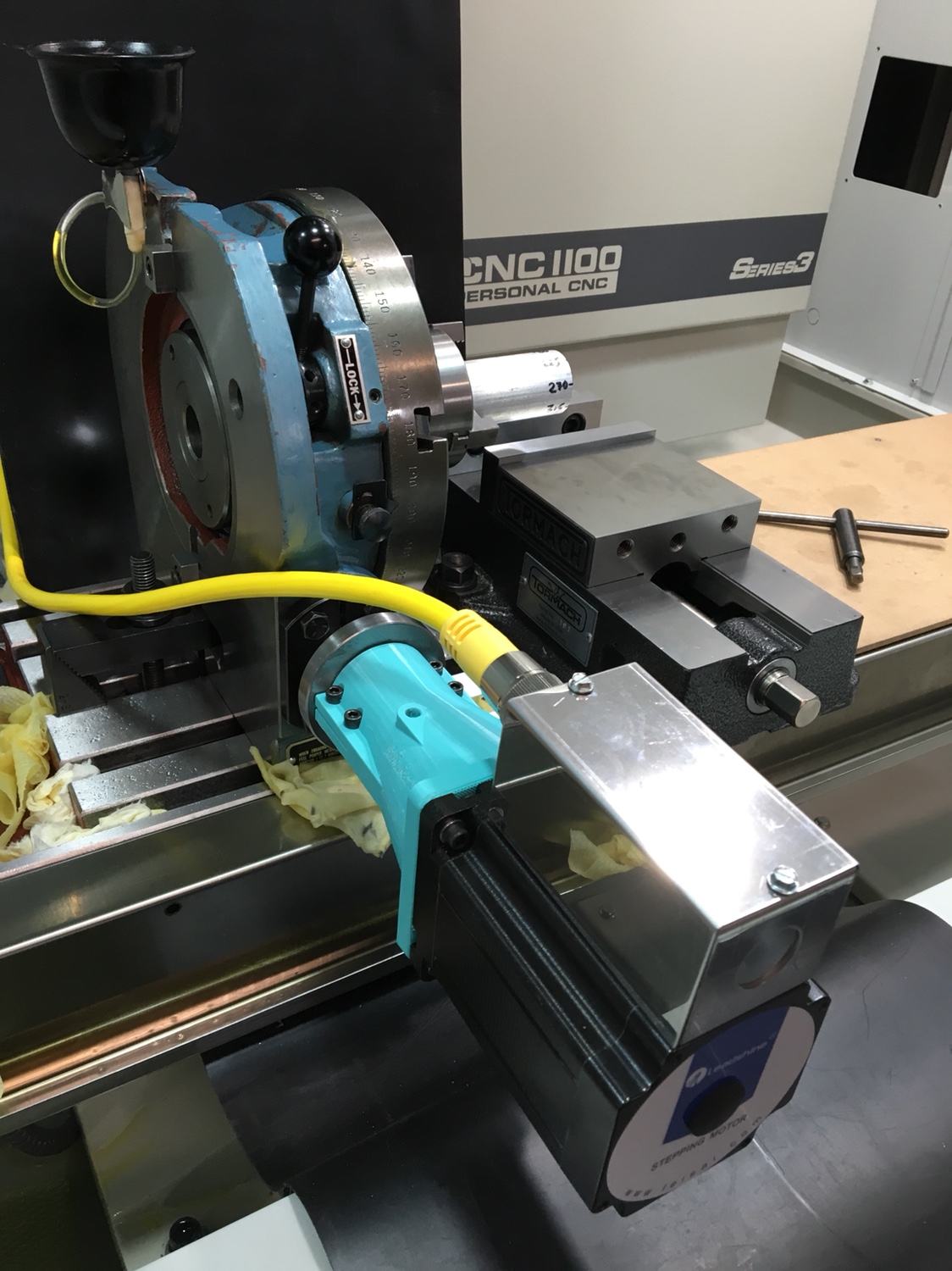

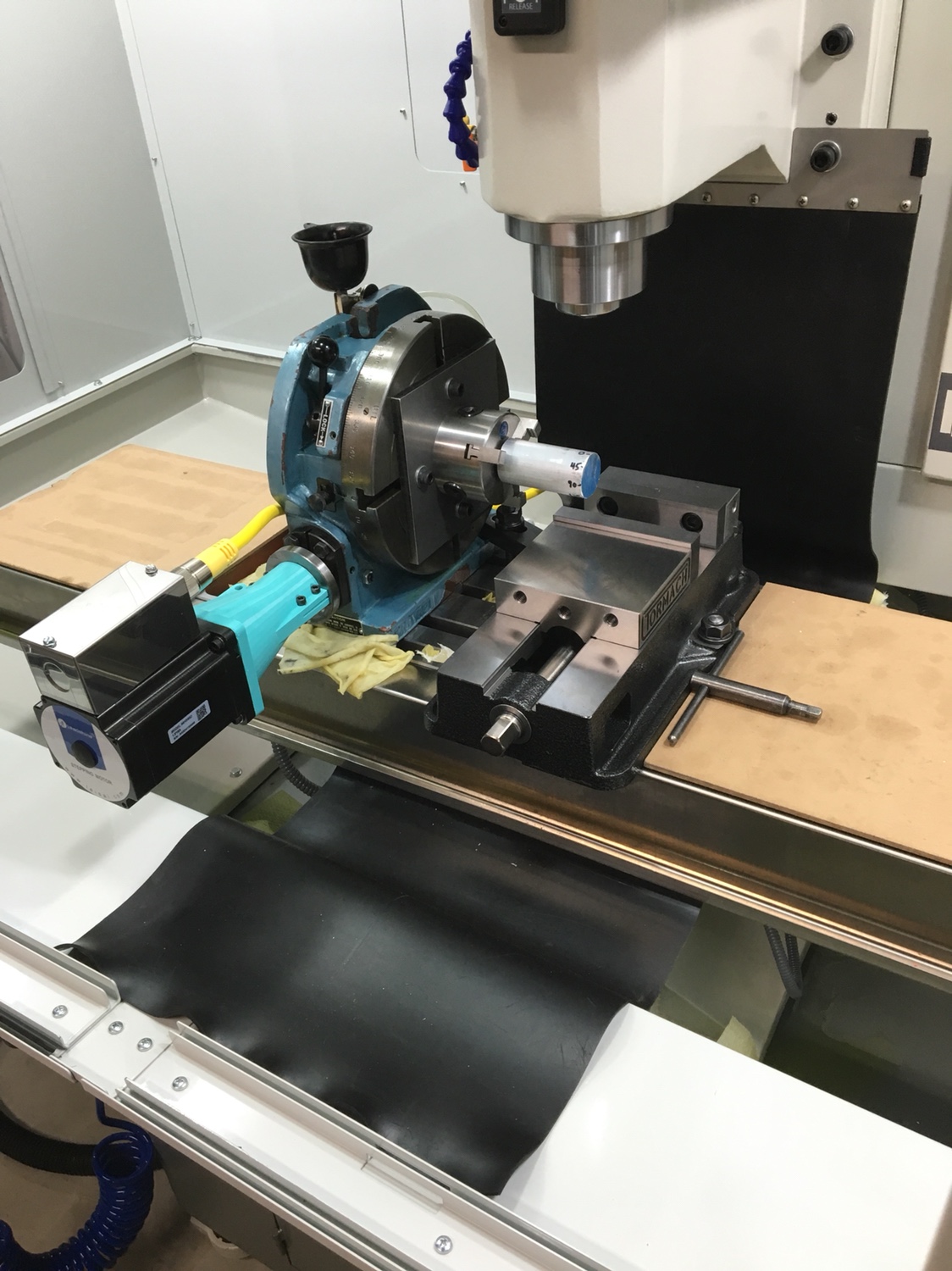

I know this may be a beat up old topic but ya I'm looking at possibly doing a little Xmas break project of converting my manual 9" Troyke rotab for use on the 1100 S3.

I picked the rotab up at an auction years ago and only had use for it once on my BP mill. Since then the thing just sits under a bench collecting dust!

Mechanically it's pretty straightforward to design and fab a Nema adapter and make it. I also understand the issues and limitations of a worm gear drive, backlash etc. and am willing to accept those vagaries. The part I'm hesitating on is the route to take with respect to the motor and drive. My first thought was to simply go to Tormach and buy the stuff I need minus the rotab itself.

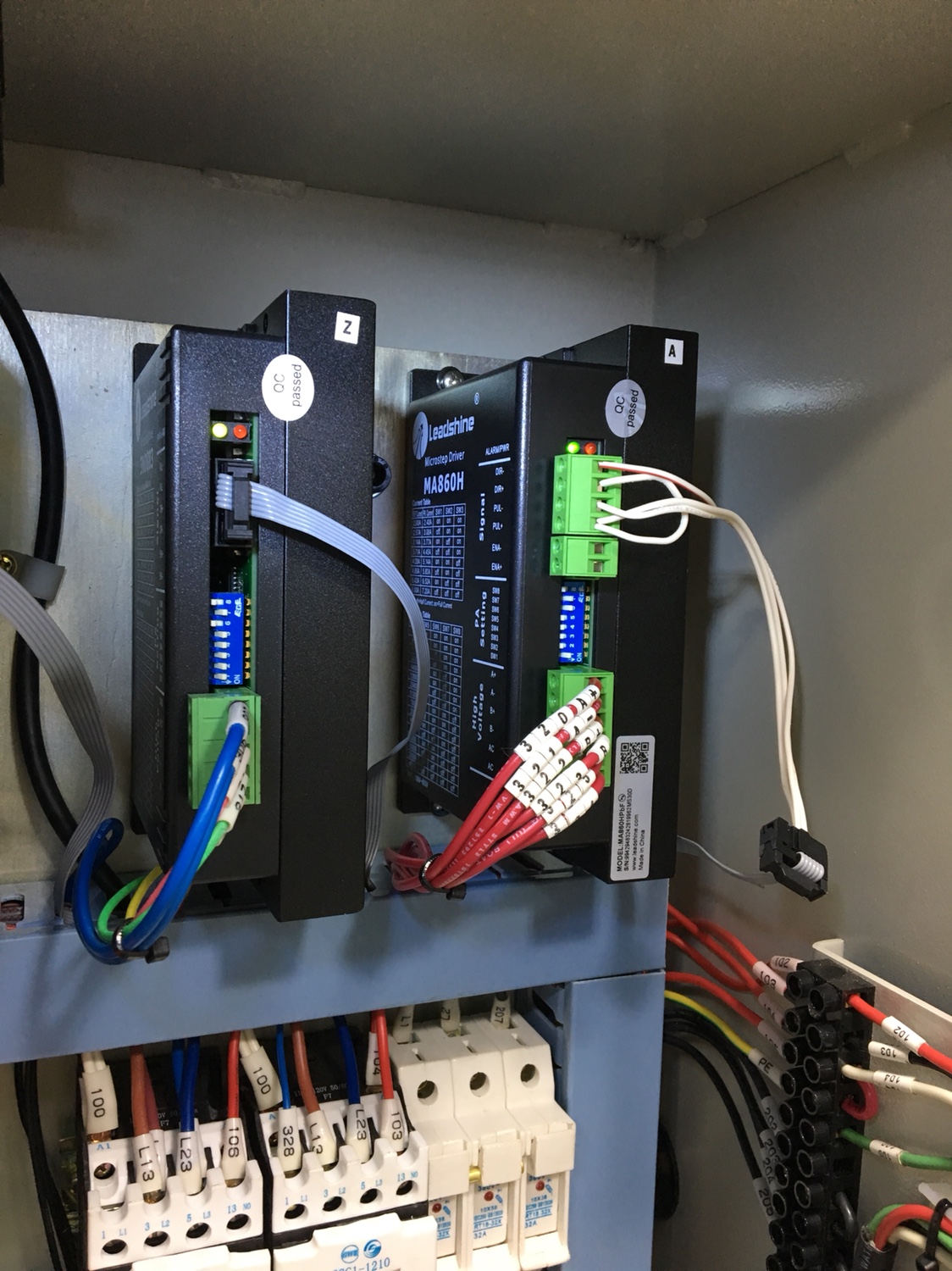

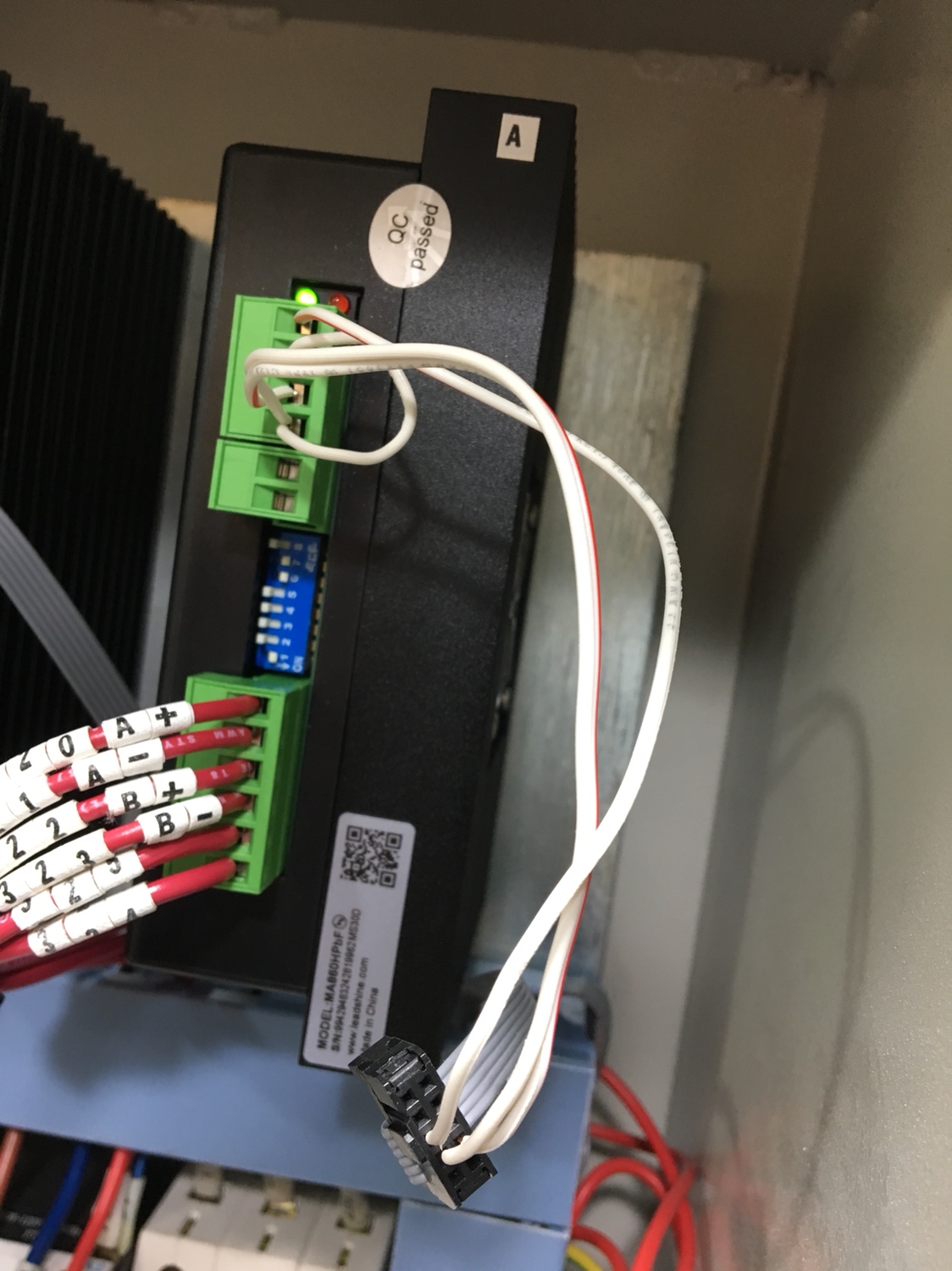

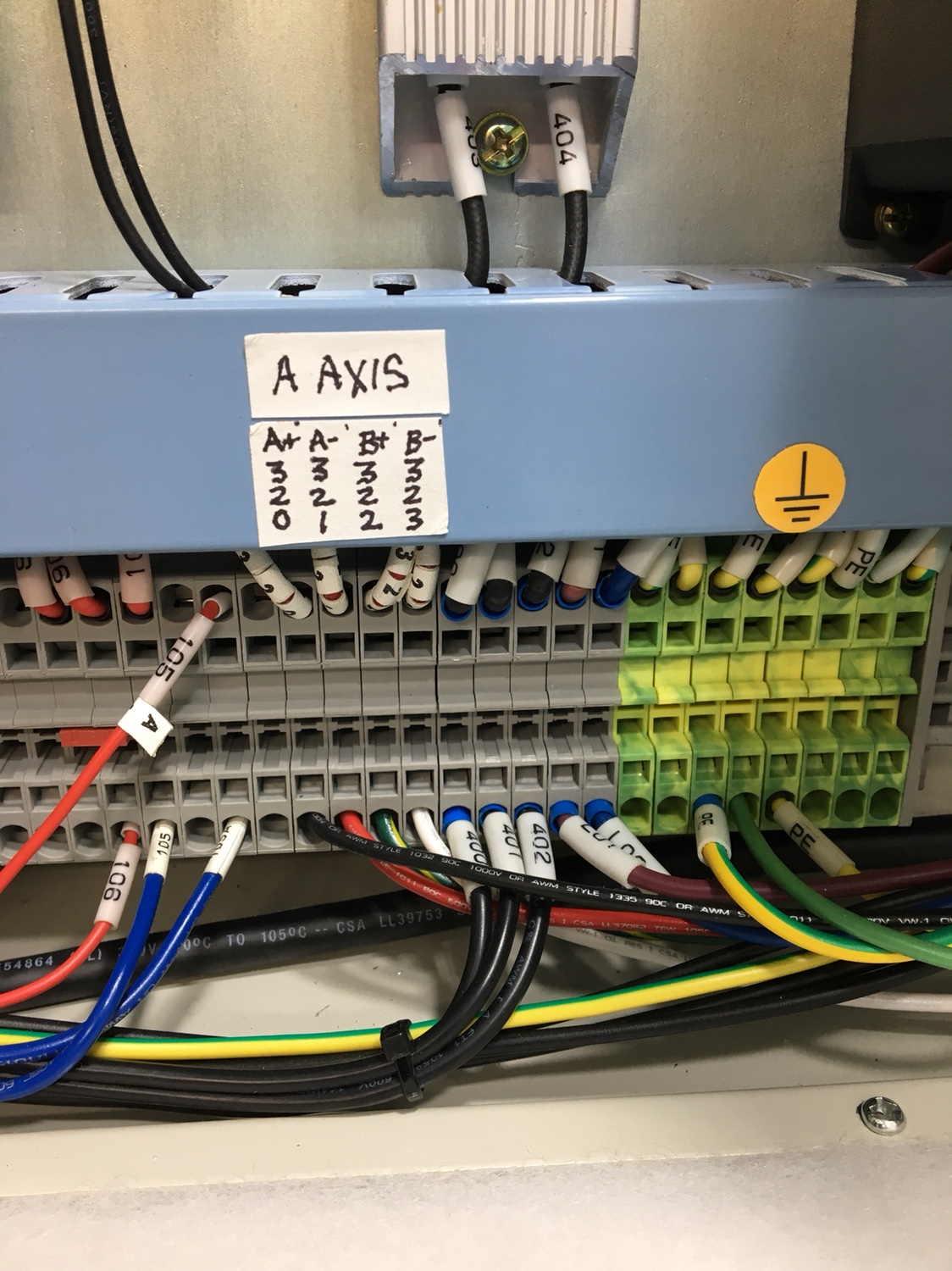

Alas, Tormach does not sell kits that include the motor, drive and plugs/wiring minus the rotab itself. They will however happily sell a replacement Leadshine MA860H drive, a nema 23 or 34 motor or an "integration" kit with the Leadshine drive and all plugs/wiring but no motor. The cost to buy a Nema 34 motor plus their drive and wiring kit ala carte comes in about $700ish which puts Tormach at a hefty premium over simply going on ebay and buying the same components. I'm not totally opposed to paying the premium for the convenience and knowing (hopefully) everything should work plug and play but I might consider the cheaper route if someone has done it successfully and can detail some of the part numbers of components they used and if there are any "gotchas" to watch for.

Has anyone here done this? I welcome any input or advice.

BTW I noticed Tormach uses the older series 1 and 2 Bi-polar two phase drives on all the 4th axis packages.

Would there be any advantages or dis-advantages using another 3-phase ND883 drive similar to the X, Y and Z on the series 3?

Here is what I'm starting with. Removed the handle

![IMG_7960[1].JPG IMG_7960[1].JPG](https://www.hobby-machinist.com/data/attachments/204/204865-f5f3fc280a63082b27f8f2c4ae61121e.jpg)

I know this may be a beat up old topic but ya I'm looking at possibly doing a little Xmas break project of converting my manual 9" Troyke rotab for use on the 1100 S3.

I picked the rotab up at an auction years ago and only had use for it once on my BP mill. Since then the thing just sits under a bench collecting dust!

Mechanically it's pretty straightforward to design and fab a Nema adapter and make it. I also understand the issues and limitations of a worm gear drive, backlash etc. and am willing to accept those vagaries. The part I'm hesitating on is the route to take with respect to the motor and drive. My first thought was to simply go to Tormach and buy the stuff I need minus the rotab itself.

Alas, Tormach does not sell kits that include the motor, drive and plugs/wiring minus the rotab itself. They will however happily sell a replacement Leadshine MA860H drive, a nema 23 or 34 motor or an "integration" kit with the Leadshine drive and all plugs/wiring but no motor. The cost to buy a Nema 34 motor plus their drive and wiring kit ala carte comes in about $700ish which puts Tormach at a hefty premium over simply going on ebay and buying the same components. I'm not totally opposed to paying the premium for the convenience and knowing (hopefully) everything should work plug and play but I might consider the cheaper route if someone has done it successfully and can detail some of the part numbers of components they used and if there are any "gotchas" to watch for.

Has anyone here done this? I welcome any input or advice.

BTW I noticed Tormach uses the older series 1 and 2 Bi-polar two phase drives on all the 4th axis packages.

Would there be any advantages or dis-advantages using another 3-phase ND883 drive similar to the X, Y and Z on the series 3?

Here is what I'm starting with. Removed the handle

![IMG_7960[1].JPG IMG_7960[1].JPG](https://www.hobby-machinist.com/data/attachments/204/204865-f5f3fc280a63082b27f8f2c4ae61121e.jpg)

Last edited: