- Joined

- Jan 21, 2013

- Messages

- 862

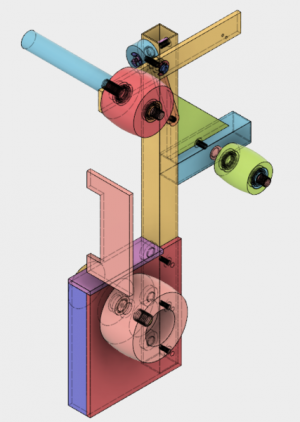

I'm designing a 42" belt grinder to attach to the right side of my new bench grinder. it gives me something to learn Fusion 360 with  I have no trouble designing things, but I have no engineering knowledge at all, so I'm never sure what is enough or too much. Almost everything I see on the net is made of 1/2 plate or similar heavy materials, but I want to use what I have on hand, and I just don't believe it needs to be that heavy. The whole thing is about 20" tall. I having a lot of fun, and the design is parameter driven, so I can make adjustments to one item and everything else adjusts to suit. Nice! This is mainly intended to be an additional tool for sharpening and shaping lathe tools and drill bits. My old 6" grinder will keep the gray wheels for doing anything else.

I have no trouble designing things, but I have no engineering knowledge at all, so I'm never sure what is enough or too much. Almost everything I see on the net is made of 1/2 plate or similar heavy materials, but I want to use what I have on hand, and I just don't believe it needs to be that heavy. The whole thing is about 20" tall. I having a lot of fun, and the design is parameter driven, so I can make adjustments to one item and everything else adjusts to suit. Nice! This is mainly intended to be an additional tool for sharpening and shaping lathe tools and drill bits. My old 6" grinder will keep the gray wheels for doing anything else.

Anyway, the questions:

1) I'm planning on using a 4" drive wheel, which will get me around 3600 SFPM. From what I've found that seems to be reasonable. Any thoughts?

2) I'm struggling on the platen support. I'm currently looking at a 1/4" plate that will hold an 1/8" plate with pyroceram plate glued to it's face. To hold it out from the tower, I'm looking at 1/4 again, anchoring where the two tabs are projecting, with an option of further contact at the top of the grinder base. There will be adjustment for belt contact and angle. Do you think that this would be rigid enough?

here's what I have so far. Clearly still a work in progress.

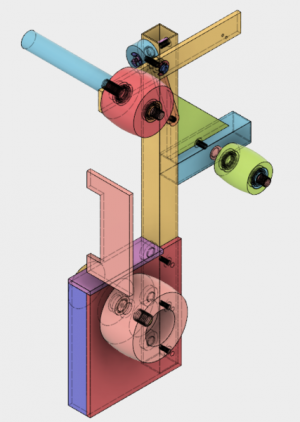

Anyway, the questions:

1) I'm planning on using a 4" drive wheel, which will get me around 3600 SFPM. From what I've found that seems to be reasonable. Any thoughts?

2) I'm struggling on the platen support. I'm currently looking at a 1/4" plate that will hold an 1/8" plate with pyroceram plate glued to it's face. To hold it out from the tower, I'm looking at 1/4 again, anchoring where the two tabs are projecting, with an option of further contact at the top of the grinder base. There will be adjustment for belt contact and angle. Do you think that this would be rigid enough?

here's what I have so far. Clearly still a work in progress.