- Joined

- Oct 10, 2018

- Messages

- 543

I posted in another thread that I bought an RF-30 type mill through an online auction. There doesn't seem to be that much information out there online about this model of machine so I thought I'd start a thread with my questions and what I figure out.

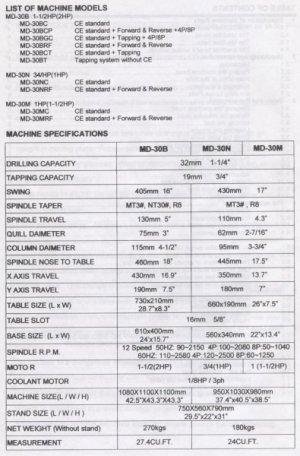

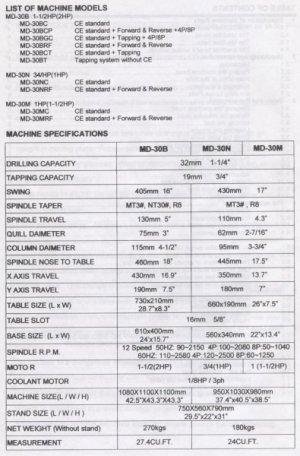

The machine was built in 2008 and sold by Busy Bee in Canada. They labelled it "B1977" but in the manual [1], it is shown as "MD-30B". I guess this means it is a copy of the Rong Fu RF-30.

[1] B1977

Basic specs are:

My machine got home and looks like this, currently:

It came with a BT-3 digital readout from Shooting Star Technology and an AL-25 power feed by Align. Haven't reinstalled the power feed since I got it home.

I did not get a proper milling vise with it and I only have a single R8 collet (1/4 inch) that was in the spindle. I did get clamping kit with the machine. Other than that and the one collet, I have no work-holding or tool-holding! As you can imagine, I'm scratching a list of what I think I want.

There is some surface rust on the table and pulleys. There is a considerable amount of dirt and grime that suggests the machine hasn't been run for a couple of years or more. Several of the handles are bent but everything that should move seems to move OK. I need to rig up a 240V extension cord into the garage before I can apply power. I need to reorganize my basement shop before I can move this (in pieces) to its home.

Craig

The machine was built in 2008 and sold by Busy Bee in Canada. They labelled it "B1977" but in the manual [1], it is shown as "MD-30B". I guess this means it is a copy of the Rong Fu RF-30.

[1] B1977

Basic specs are:

My machine got home and looks like this, currently:

It came with a BT-3 digital readout from Shooting Star Technology and an AL-25 power feed by Align. Haven't reinstalled the power feed since I got it home.

I did not get a proper milling vise with it and I only have a single R8 collet (1/4 inch) that was in the spindle. I did get clamping kit with the machine. Other than that and the one collet, I have no work-holding or tool-holding! As you can imagine, I'm scratching a list of what I think I want.

There is some surface rust on the table and pulleys. There is a considerable amount of dirt and grime that suggests the machine hasn't been run for a couple of years or more. Several of the handles are bent but everything that should move seems to move OK. I need to rig up a 240V extension cord into the garage before I can apply power. I need to reorganize my basement shop before I can move this (in pieces) to its home.

Craig