- Joined

- Dec 17, 2013

- Messages

- 23

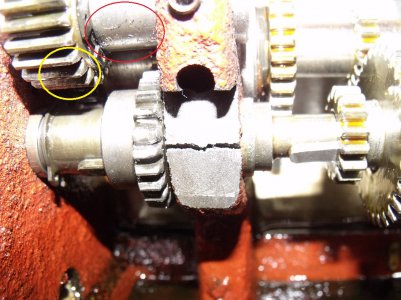

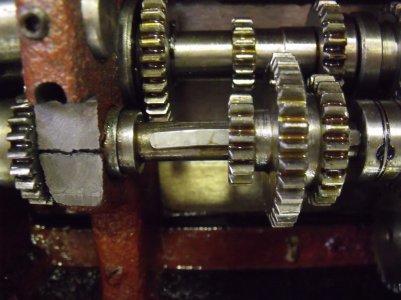

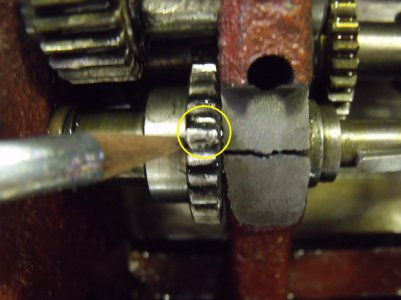

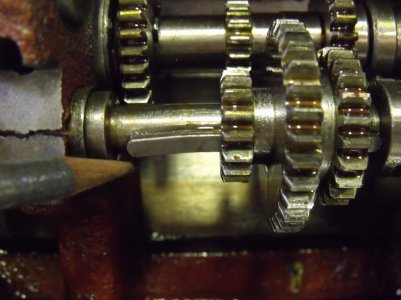

Howdy all, new here, and fairly new to machining. Bought a Craftex CX701 in July 2012, have barely 10 hours on it; on the weekend was getting ready to face a piece of plate for a wheel adapter, hadn't started the cut yet, when the motor pulled down like it was cutting to hard, then crunch-munch. Took the gearbox cover off, found it had broke the web inside that supports the shafts in the middle of the gearbox, trashed 3 gears, and one shaft. Thankfully, Busy Bee tools, where I bought it, is covering the parts for the repair; however, likely won't have the parts until spring. It was always stiff to move the shifters, on it, but put that down to being new and an offshore machine. In hindsight should have checked it out sooner. Has anyone here had or heard of this problem before on same or similar machines?

Thanks in advance.

Btw, great site!

Drifter1885

Thanks in advance.

Btw, great site!

Drifter1885