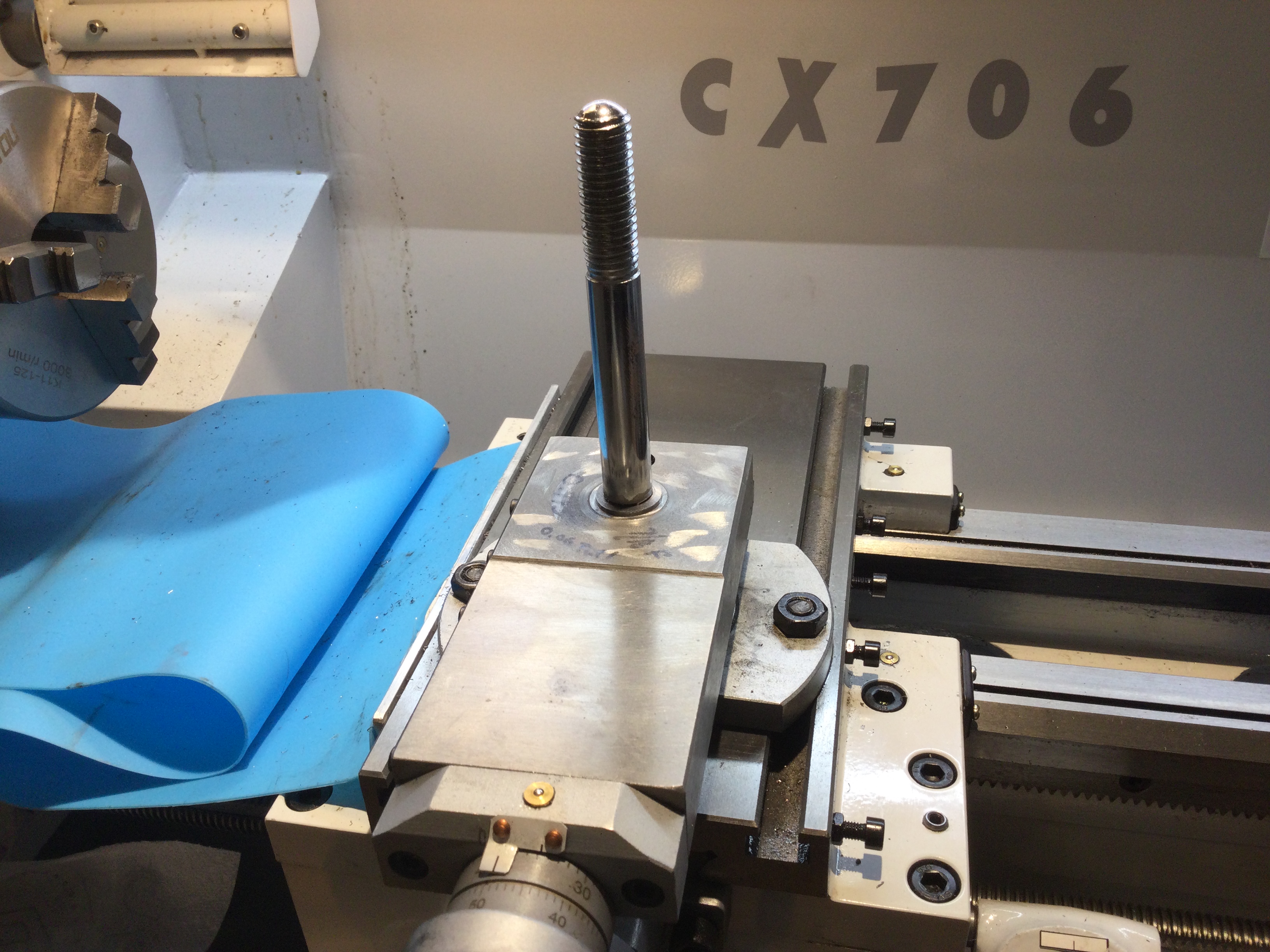

I recently purchased a Busy Bee Craftex CX706 10” lathe and was not thrilled with the supplied tool post. This particular lathe is similar to the Precision Mathews and Grizzly 10” lathes, however they all seem to use a slightly different method to secure the tool post. The CX706 uses a wimpy M8 stud. The stud is sort of semi tight fitted, non threaded (on the bottom) press in from the bottom with a roll pin to prevent rotation. There is also a round boss on top that fits inside the original tool post.

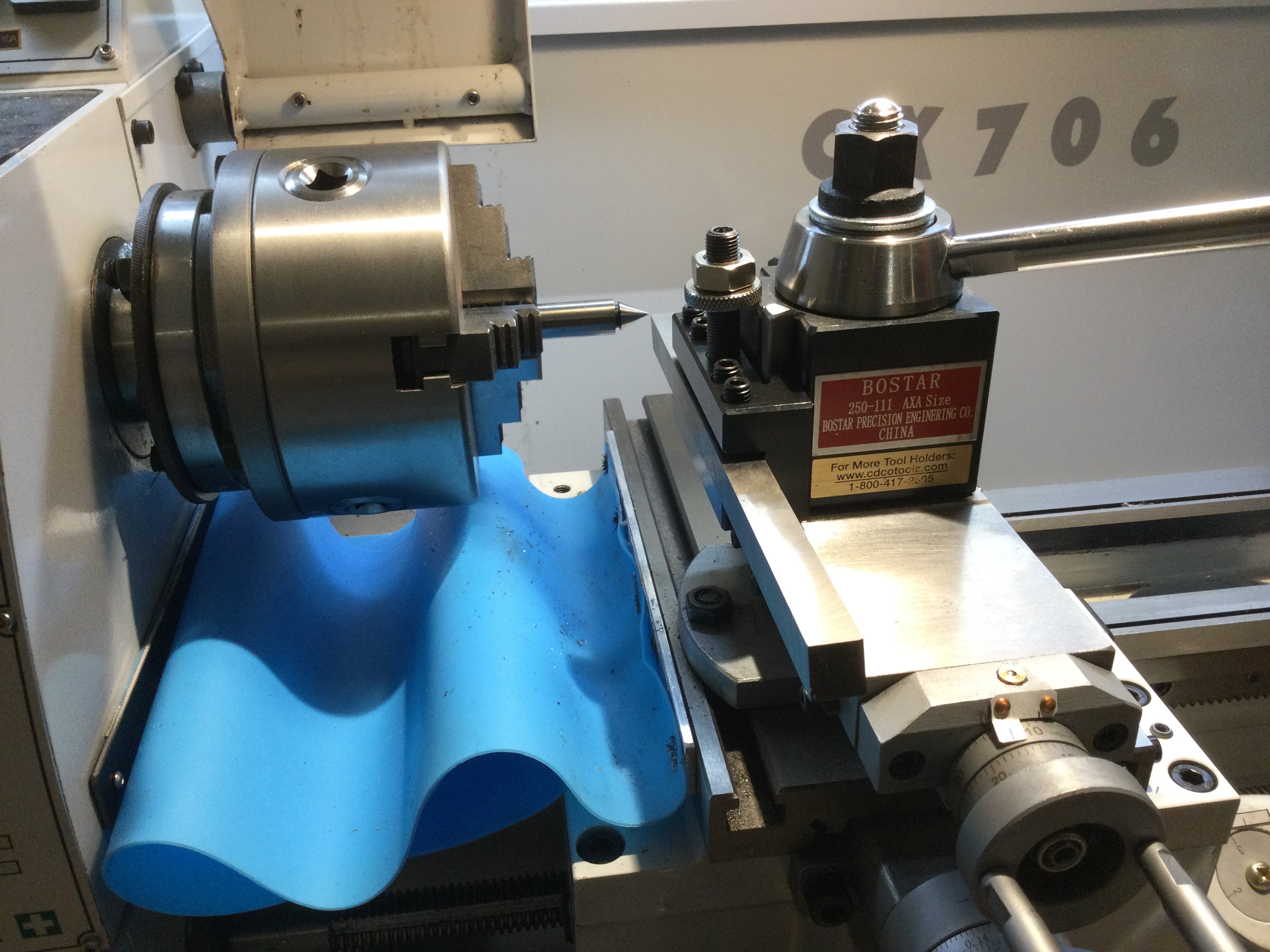

After a quick Google search, I decided to go with a Bostar wedge type AXA tool post. This tool post came with a beefy 14mm stud. Install was pretty straightforward, but did require a few tweaks, so I’m showing what I did incase anyone wants to see the approach I took.

1) turn down the diameter of the short end of the supplied 14mm stud to prep for 7/16 fine thread for the bottom side of the thread

2) rethread the bottom end of the stud for 7/16-20 (fine) thread.

3) remove the tool post and compound.

4) the original m8 stud easily taps out with a plastic hammer

5) the existing untapped hole is very close to ideal size for a 7/16-20 thread, so tap it.

6) the Bostar tool post has a slightly recessed opening on the bottom, so I decided to take advantage of that and leave a small round boss at the top of the compound to register the new tool post.

7) mill or turn the existing large boss to a reduced diameter of about 740mils to match the recessed hole in the new tool post.

8) mill the 740mil boss down so that is only about 65mils tall.

9) install the stud with red lock tite and tighten firmly.

10) reinstall the compound, drop on the QC tool post and have fun.

After a quick Google search, I decided to go with a Bostar wedge type AXA tool post. This tool post came with a beefy 14mm stud. Install was pretty straightforward, but did require a few tweaks, so I’m showing what I did incase anyone wants to see the approach I took.

1) turn down the diameter of the short end of the supplied 14mm stud to prep for 7/16 fine thread for the bottom side of the thread

2) rethread the bottom end of the stud for 7/16-20 (fine) thread.

3) remove the tool post and compound.

4) the original m8 stud easily taps out with a plastic hammer

5) the existing untapped hole is very close to ideal size for a 7/16-20 thread, so tap it.

6) the Bostar tool post has a slightly recessed opening on the bottom, so I decided to take advantage of that and leave a small round boss at the top of the compound to register the new tool post.

7) mill or turn the existing large boss to a reduced diameter of about 740mils to match the recessed hole in the new tool post.

8) mill the 740mil boss down so that is only about 65mils tall.

9) install the stud with red lock tite and tighten firmly.

10) reinstall the compound, drop on the QC tool post and have fun.