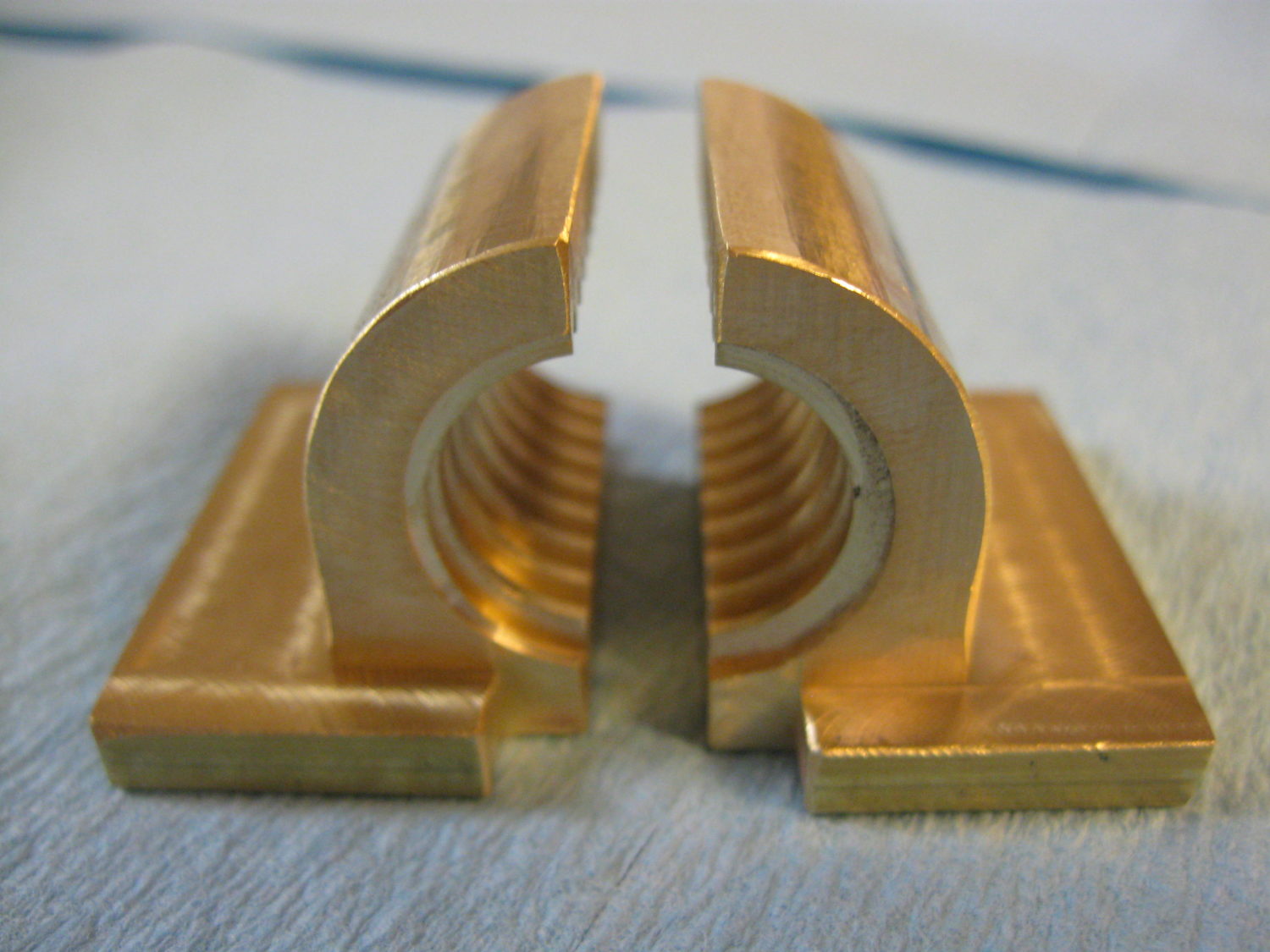

I have a craftsman 101.28940 that has recently started skipping teeth in the ~10" of travel closest to the chuck. I can only assume this is either due to leadscrew or half nut wear (or both). When I take a look at the half nut while it's engaged, it looks like the upper portion of the half nut is jumping around. Initially I thought it may be due to some run out on the leadscrew, but I measured the run out to be .005". I was able to get into the tight space and clean the half nut, along with the leadscrew but this made no difference.

Before I tear this thing apart, is there any adjustment for the half nut? It feels to me like the upper portion of the nut is loose. There is definitely some wear on the leadscrew, so I assume the half nut is pretty worn as well but I'd like to avoid replacing the screw if I can.

-Adam.

Before I tear this thing apart, is there any adjustment for the half nut? It feels to me like the upper portion of the nut is loose. There is definitely some wear on the leadscrew, so I assume the half nut is pretty worn as well but I'd like to avoid replacing the screw if I can.

-Adam.