- Joined

- Apr 8, 2018

- Messages

- 7

Hi all. I’m new to this site. I just recently sold my Craftsman Atlas 618 lathe and bought a 12” Craftsman Atlas for the same price.

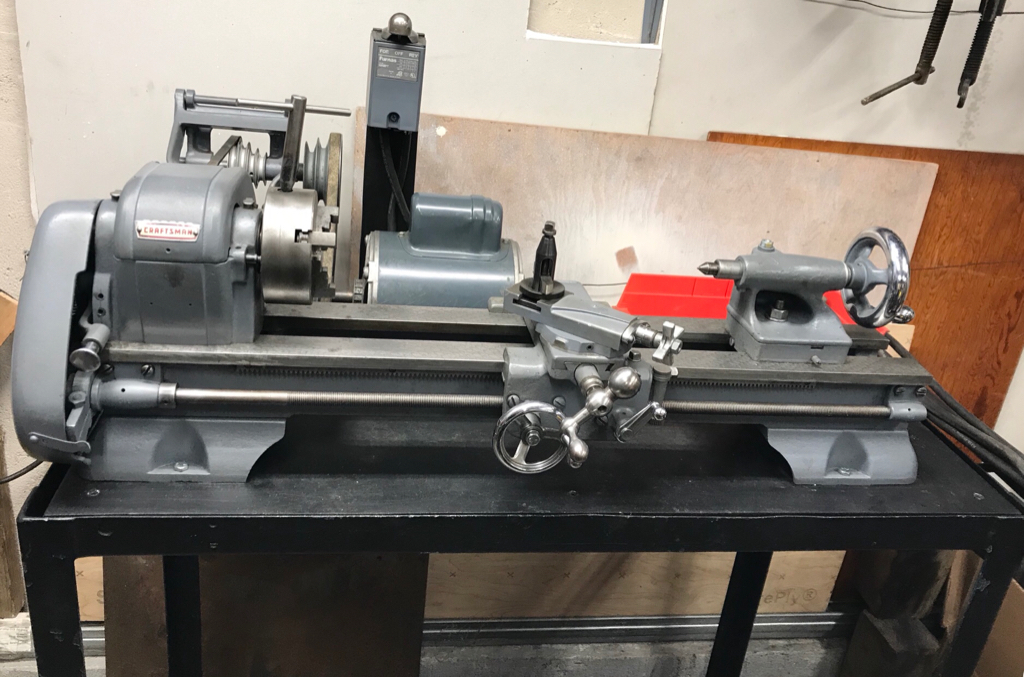

Here is the old 618. I bought it restored.

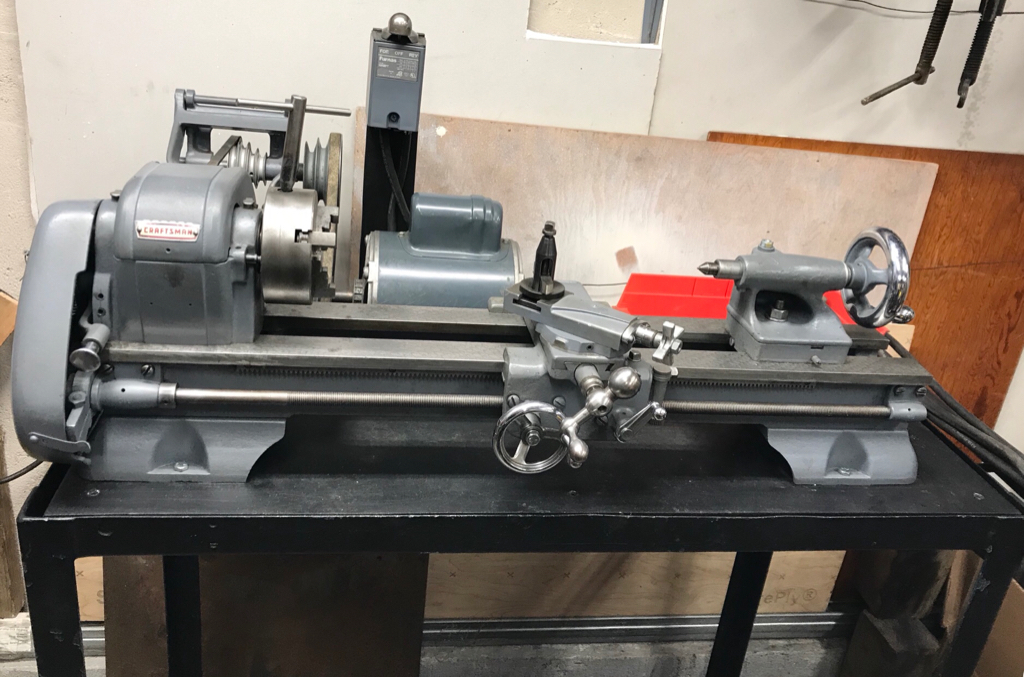

The replacement.

I have uploaded all the images from the beginning from disassemble. Most pictures on the album have a description.

https://www.facebook.com/pg/veepsgarage/photos/?tab=album&album_id=1925763394401447

Please let me know if the link to the pictures doesn’t work. So far I’ve disassembled the lathe and have started degreasing. It’s in very good shape but I do have to paint the tailstock and a few items. I will try to match the paint so I can just scuff up and hopefully brush on new paint on the parts that have paint chipped.

Thanks for following along.

Here is the old 618. I bought it restored.

The replacement.

I have uploaded all the images from the beginning from disassemble. Most pictures on the album have a description.

https://www.facebook.com/pg/veepsgarage/photos/?tab=album&album_id=1925763394401447

Please let me know if the link to the pictures doesn’t work. So far I’ve disassembled the lathe and have started degreasing. It’s in very good shape but I do have to paint the tailstock and a few items. I will try to match the paint so I can just scuff up and hopefully brush on new paint on the parts that have paint chipped.

Thanks for following along.

Last edited: