B

British Steel

Forum Guest

Register Today

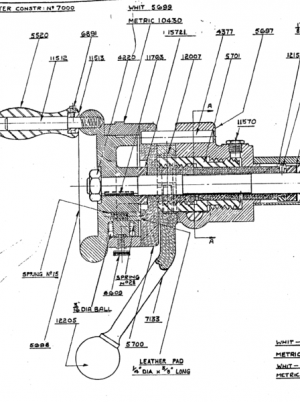

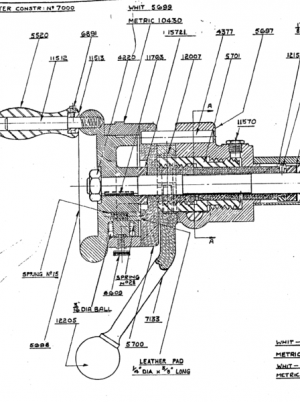

I like the Monarch stop, but the Holbrook quick-withdraw is a lot quicker and just as repeatable (well under a thou", mine appears to be about 2 tenths) - it takes a 1/4 turn, retracts / advances the cross-slide through 3/8" by a double (left and right-hand) threaded collar between feed screw housing and handwheel (the widely-hatched 5701 below):

The double-threaded 5701 is rotated by the lever 7133, rotating out of housing 5697 and also rotating feedscrew carrier 1215 out of 5701 - the dowel pin 4377 holds everything in alignment, and it can be locked up by a pair of collets should you not need the quick-withdrawal (or set to your choice of friction).

N.B. - not my work, no CAD package was harmed in the preparation of this picture...

Dave H. (the other one)

The double-threaded 5701 is rotated by the lever 7133, rotating out of housing 5697 and also rotating feedscrew carrier 1215 out of 5701 - the dowel pin 4377 holds everything in alignment, and it can be locked up by a pair of collets should you not need the quick-withdrawal (or set to your choice of friction).

N.B. - not my work, no CAD package was harmed in the preparation of this picture...

Dave H. (the other one)

If I were to do a lot of numbering, I would have considered building one

If I were to do a lot of numbering, I would have considered building one