-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

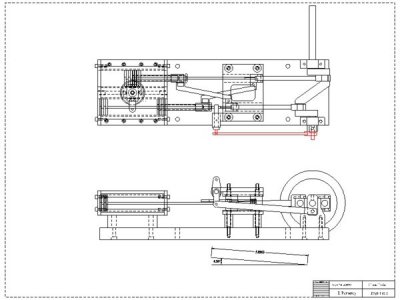

Cross-Twin Engine

- Thread starter Cobra

- Start date

- Joined

- Apr 24, 2013

- Messages

- 709

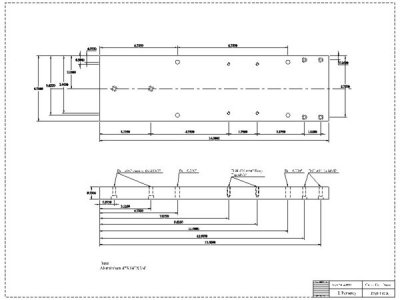

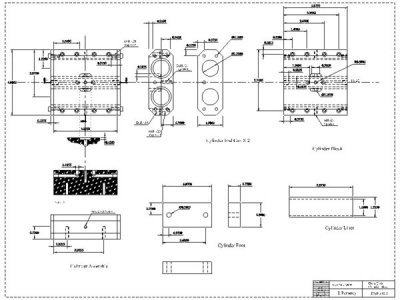

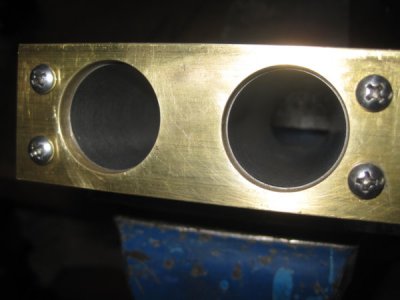

Started on the cylinder block. I didn't have any 1-1/2" X 4" flat bar so decided to make it out of two pieces of 3/4" X 4" rather than order from the States.

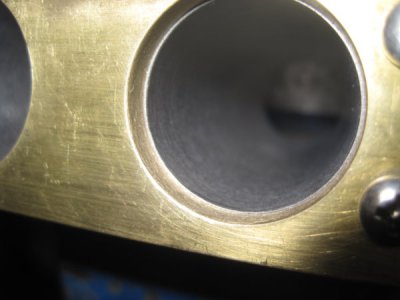

I have just used the aluminium in the past for the cylinder but this time with the split block I decided to make cast iron liners for the cylinders. The initial plan was to have threaded caps on the ends of the cylinders to clamp them into the cylinder block as in the PDF Cross Twin 3a.

Good thing the planning was being done by the Mexican pool with a beer because the second version would just use brass plates on each end of the block to hold the liners in place. Much easier than threading!

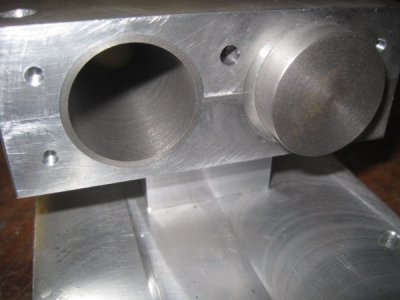

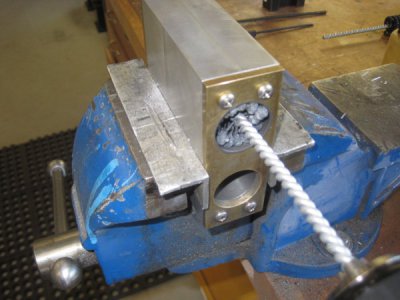

Started by milling to two halves of the cylinder block in preparation for bolting them together.

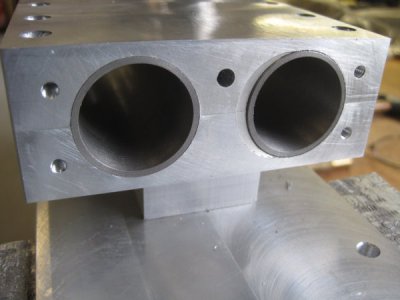

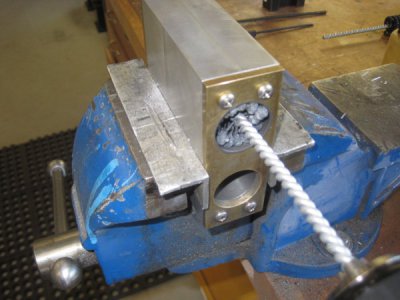

Block halves now bolted together and ready to start the boring of the cylinders.

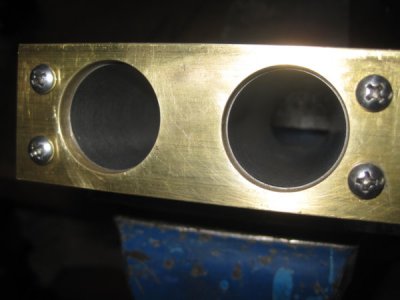

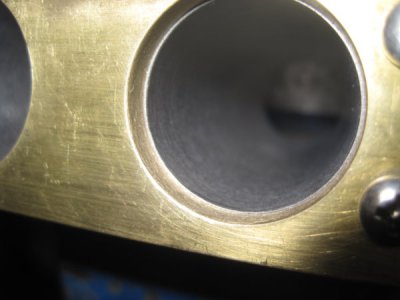

Cylinder block ready for the cast iron liners and then the retaining plates.

I have just used the aluminium in the past for the cylinder but this time with the split block I decided to make cast iron liners for the cylinders. The initial plan was to have threaded caps on the ends of the cylinders to clamp them into the cylinder block as in the PDF Cross Twin 3a.

Good thing the planning was being done by the Mexican pool with a beer because the second version would just use brass plates on each end of the block to hold the liners in place. Much easier than threading!

Started by milling to two halves of the cylinder block in preparation for bolting them together.

Block halves now bolted together and ready to start the boring of the cylinders.

Cylinder block ready for the cast iron liners and then the retaining plates.

Attachments

- Joined

- Apr 24, 2013

- Messages

- 709

- Joined

- Apr 24, 2013

- Messages

- 709

Well the hones arrived this morning. I have to say that, for Canada, I am getting to like KBC almost as much as McMaster-Carr. They have a great selection of products and two day delivery to the door for a lot less than McMaster.

The two hones and some lathe tools arrived for $8 instead of the $40-50 from McMaster.

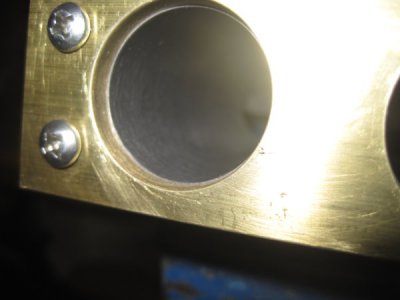

I ordered two hones, one at 120 grit and one at 240.

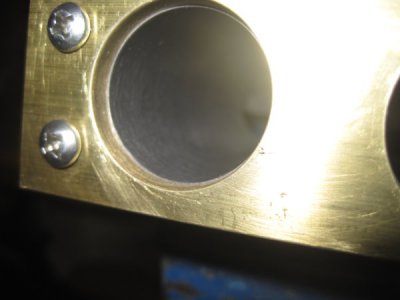

The cylinders are 1.100" and the 1-1/8" hones worked fine.

That's it for the cylinder block for now. Next will be the bearing blocks for the crankshaft.

Should be straight forward and a little rotary table work at the end to finish the top of the blocks.

The two hones and some lathe tools arrived for $8 instead of the $40-50 from McMaster.

I ordered two hones, one at 120 grit and one at 240.

The cylinders are 1.100" and the 1-1/8" hones worked fine.

That's it for the cylinder block for now. Next will be the bearing blocks for the crankshaft.

Should be straight forward and a little rotary table work at the end to finish the top of the blocks.

- Joined

- Apr 24, 2013

- Messages

- 709

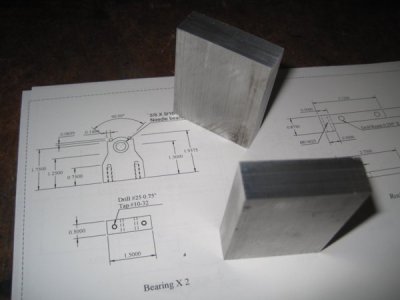

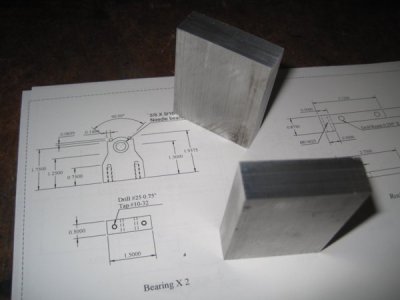

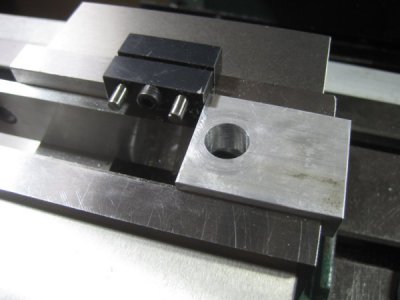

Completed the bearing blocks for the crank. The crank will be 3/8 so I used a pair of 3/8 X 9?16 X 1/2 needle bearings.

Squaring up the 1/2" stock for the two blocks.

Drilled and reamed to 9/16 for the bearings.

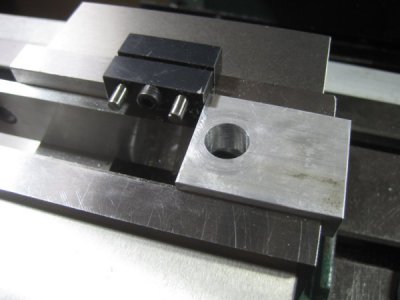

Needed to use the rotary table for the tops of the two blocks.

At one point in the past I made a taper fitting for the centre of the RT that will accept a 3/8 pin.

The centre pin makes set up of the bearing straight forward. I now have a set of pins that step up or down from the 3/8 in the taper plug.

Used the side of the block to set up square at the 0 degree point.

I had to get an extended length mill from KBC to reach all the way through the 1/2" material. Decided on double ended and ordered two to cover my uncertainty milling with a 1/8 cutter 1/2" deep.

Turned out that I didn't need the three extra cutting surfaces - the first one lasted and I didn't break it!

Plunge cut in and around the 90 degree arc and out the other side and then did a cleanup climb milling pass to take off the last 5 thou.

Blocks finished and fit to the base.

Cross head guides next.

Squaring up the 1/2" stock for the two blocks.

Drilled and reamed to 9/16 for the bearings.

Needed to use the rotary table for the tops of the two blocks.

At one point in the past I made a taper fitting for the centre of the RT that will accept a 3/8 pin.

The centre pin makes set up of the bearing straight forward. I now have a set of pins that step up or down from the 3/8 in the taper plug.

Used the side of the block to set up square at the 0 degree point.

I had to get an extended length mill from KBC to reach all the way through the 1/2" material. Decided on double ended and ordered two to cover my uncertainty milling with a 1/8 cutter 1/2" deep.

Turned out that I didn't need the three extra cutting surfaces - the first one lasted and I didn't break it!

Plunge cut in and around the 90 degree arc and out the other side and then did a cleanup climb milling pass to take off the last 5 thou.

Blocks finished and fit to the base.

Cross head guides next.

- Joined

- Dec 27, 2014

- Messages

- 4,056

Your mention of Crossheads puts me in an uncomfortable state, not you but my memory. I had a 9" diameter, #156 cast iron crosshead in a lathe, to turn the OD. got done, put the sling on the jib boom around the cross head, took out the center bolt, and the crosshead fell between the ways into the chip pan, taking my right hand with it. Mashed hell out of the first two fingers, end joint only. I spent a month on light duty, taking inventory. This had to be 30 years ago and it still makes my knees weak.