- Joined

- Jul 26, 2013

- Messages

- 584

Hello all,

First, I want to wish all of you a Happy New Year...

I started a thread about this horizontal mill here... http://www.hobby-machinist.com/showthread.php/23622-Cunliffe-Horizontal-Milling-Machine

... but decided to start a new thread here, concerning the electrical issues that I am having.

I recieved some replacement fuses from a kind friend in England over the Christmas holidays, to replace the 50 amp fuse that I burned out while trying to start the 2-speed motor on the mill.

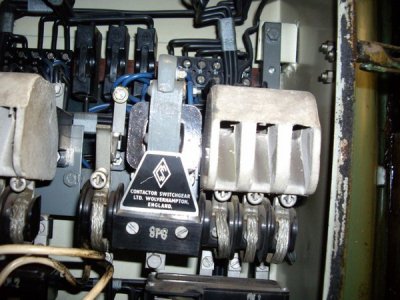

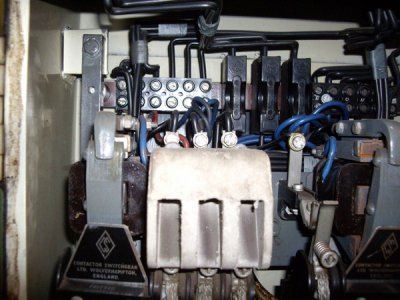

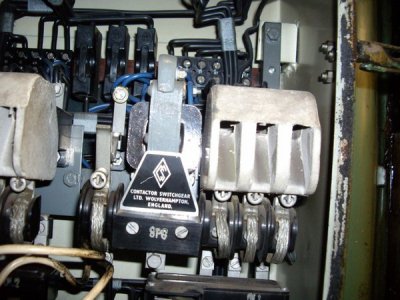

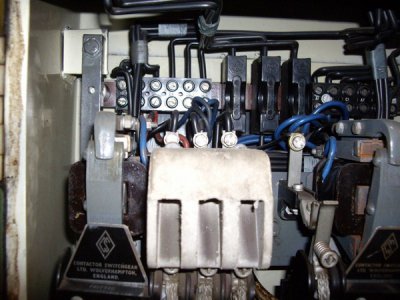

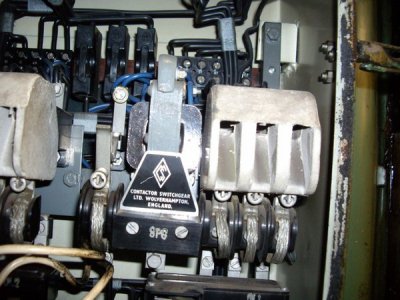

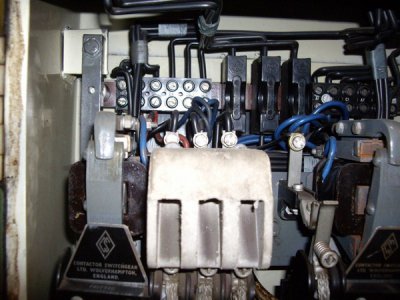

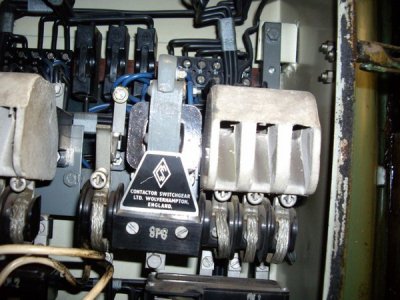

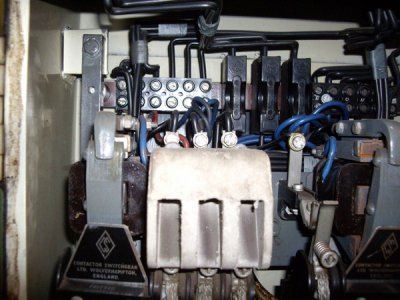

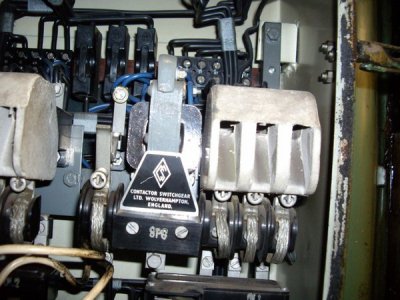

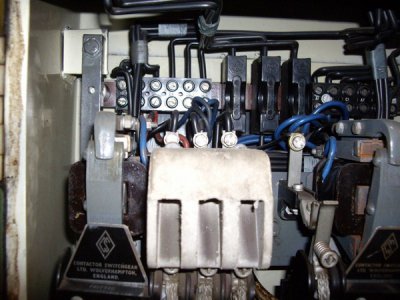

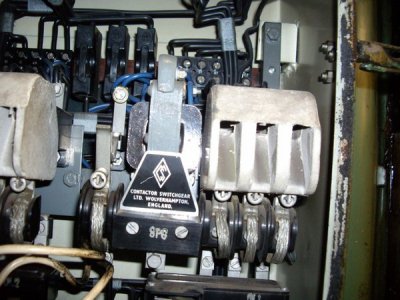

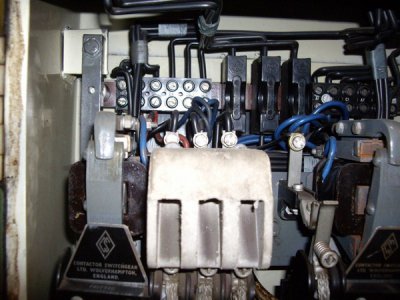

Here are a few pics of the electrical panel to start with...

Here's a pic of the mill...

This mill has a 2-speed motor, rated at 4hp (low speed) and 8hp (high speed). I have it powered with a 10hp RPC. I have no trouble at all in powering it at the low speed setting and can take a good cut with it. But when I try to power it up at high speed, the contactor cuts out. As well, I finally burnt out a 50amp fuse while trying to power it up at high speed after a few tries.

I have to go have lunch and will be back with more info...

Brian

First, I want to wish all of you a Happy New Year...

I started a thread about this horizontal mill here... http://www.hobby-machinist.com/showthread.php/23622-Cunliffe-Horizontal-Milling-Machine

... but decided to start a new thread here, concerning the electrical issues that I am having.

I recieved some replacement fuses from a kind friend in England over the Christmas holidays, to replace the 50 amp fuse that I burned out while trying to start the 2-speed motor on the mill.

Here are a few pics of the electrical panel to start with...

Here's a pic of the mill...

This mill has a 2-speed motor, rated at 4hp (low speed) and 8hp (high speed). I have it powered with a 10hp RPC. I have no trouble at all in powering it at the low speed setting and can take a good cut with it. But when I try to power it up at high speed, the contactor cuts out. As well, I finally burnt out a 50amp fuse while trying to power it up at high speed after a few tries.

I have to go have lunch and will be back with more info...

Brian