- Joined

- Dec 3, 2013

- Messages

- 1,844

So finally getting to projects that make things other than tools and equipment.

I'm posting this in the projects area since it involves making a custom form tool.

I shoot a sport called Metallic Silhouette which is shot off-hand (standing) with no support, slings or special clothing. Targets are metal silhouettes of chickens, pigs, turkeys and rams set an different distances. There are several disciplines ranging from air rifles with targets out to 60 meters and high power out to 500 meters. One of the disciplines I shoot is lever action pistol cartridge with a .357 lever action rifle. I cast and shoot lead bullets with this rifle. Most commercial molds for the .357 are wad cutters or semi-wad cutters. I have not found a commercial mold with a round nose that can be gas checked. Pistol cartridge silhouette is out to 100 meters and a few of the commercial semi-wad cutter designs do well but I wanted something with a better ballistic coefficient.

There are several companies that will make custom molds from your designs but they can cost $200-$300 per mold. I set about to make my own. Lee Precision offers mold blanks that come with handles so I ordered a pair of those to get started. Lee Precision also has a guide sheet for creating drawings for them to make custom molds for customers. Armed with this info I set about designing a bullet.

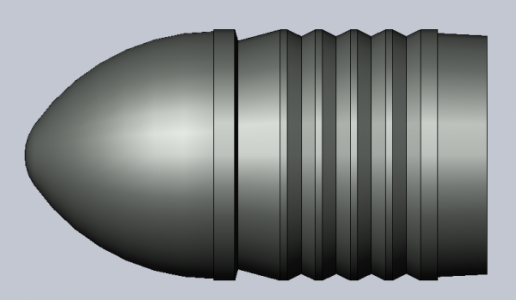

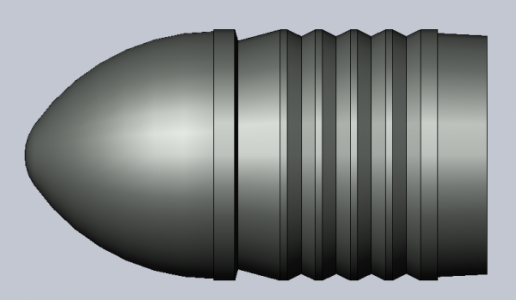

This is the final design. These will be powder coated so I chose to use the Lee small lube grooves instead of a large lube groove or no lube groove. The theory is the bullets will be run through a final sizing die and I wanted the body to have a little room to compress without elongating the bullet if it had no grooves while keeping a larger surface area for barrel land engagement. The target weight with range lead & gas check is 155-160 grains.

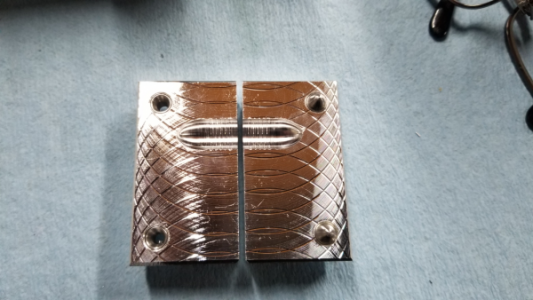

To cut the mold I decided to make a one flute form tool from O-1 drill rod. Several HSS tool bits were needed to cut the various grooves and nose profile.

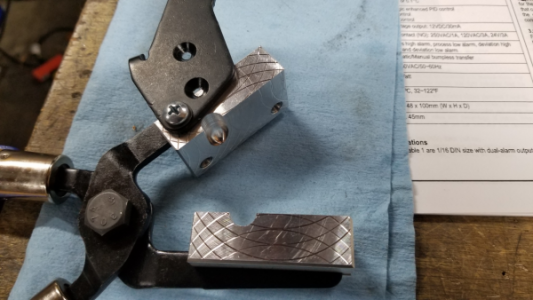

Tools from left to right are (1) basic turning/facing tool. (2) Nose form tool. This tool has a double radius, .075 at the tip and .312 beyond. I printed the profile at full scale, glued it to the tool bit blank and rough ground by hand on the bench grinder. Finishing was with a diamond bit in a die grinder. (3) Case crimp groove tool at 15 deg with a 90. (4) Lube groove tool, each side is 26 deg. (5) gas check relief tool at 3 deg.

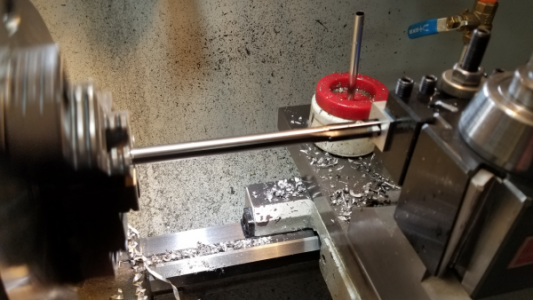

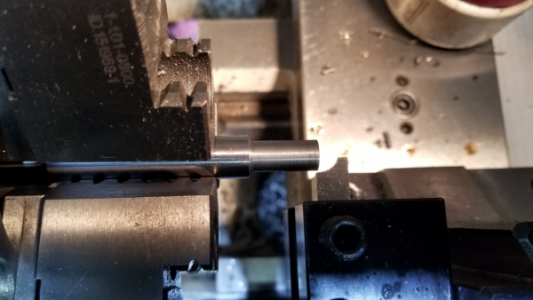

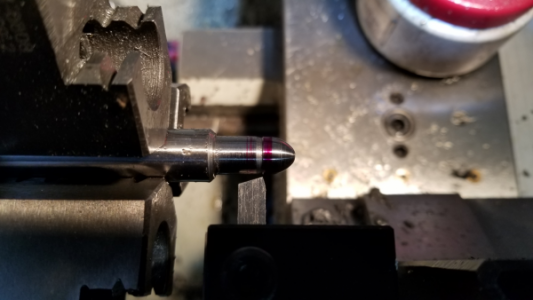

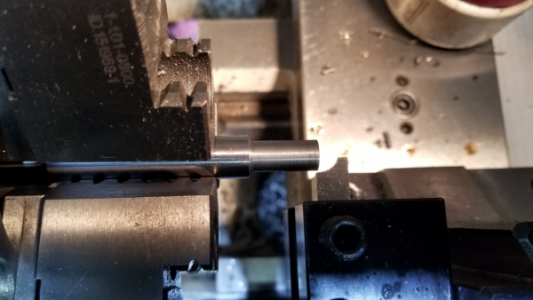

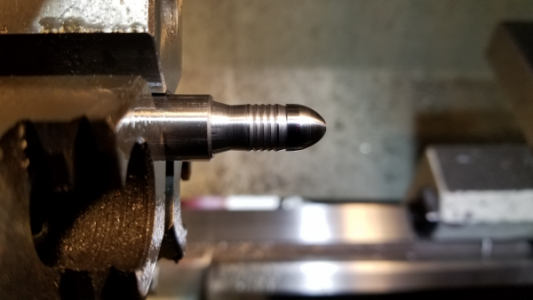

1/2" drill rod turned to .359" ready for the nose form.

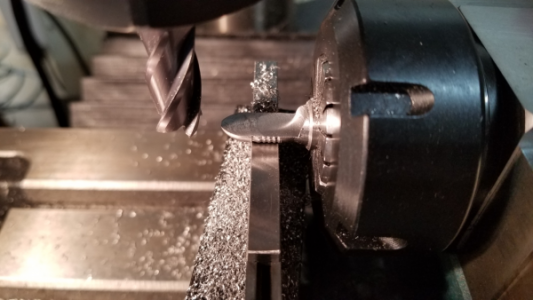

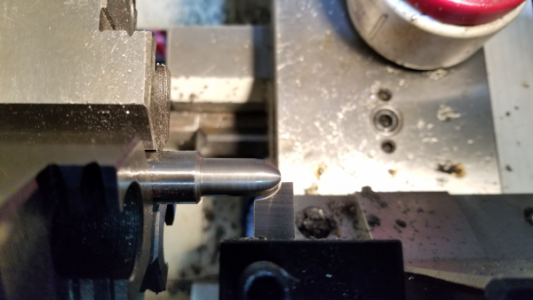

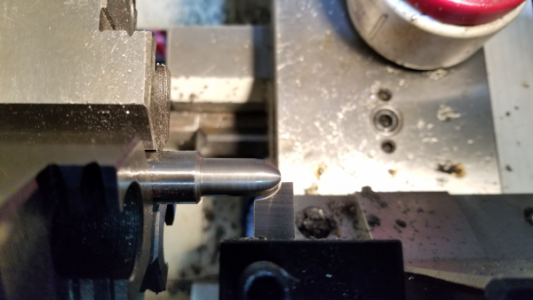

Nose profile cut.

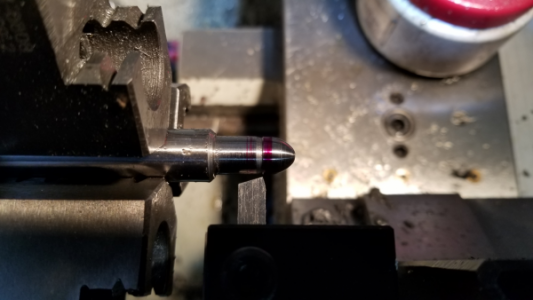

Hand sanded w/320 to .358"

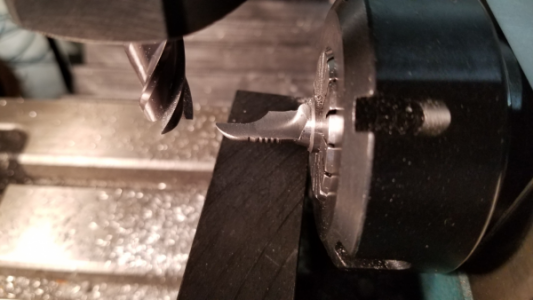

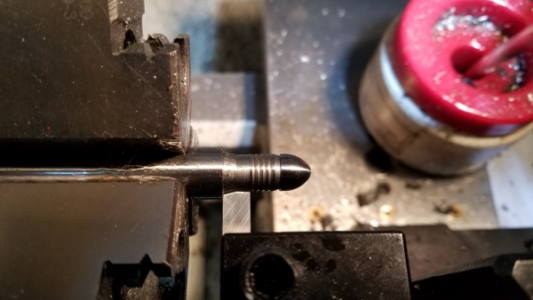

Crimp groove cut

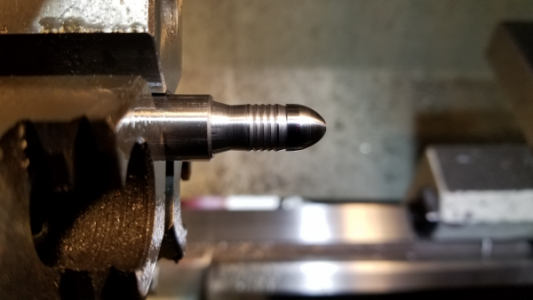

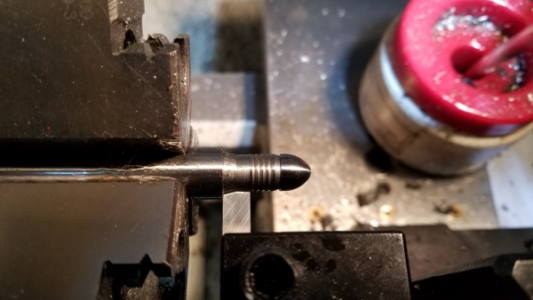

Lube grooves cut

Gas check relief cut

Final profile

I'm posting this in the projects area since it involves making a custom form tool.

I shoot a sport called Metallic Silhouette which is shot off-hand (standing) with no support, slings or special clothing. Targets are metal silhouettes of chickens, pigs, turkeys and rams set an different distances. There are several disciplines ranging from air rifles with targets out to 60 meters and high power out to 500 meters. One of the disciplines I shoot is lever action pistol cartridge with a .357 lever action rifle. I cast and shoot lead bullets with this rifle. Most commercial molds for the .357 are wad cutters or semi-wad cutters. I have not found a commercial mold with a round nose that can be gas checked. Pistol cartridge silhouette is out to 100 meters and a few of the commercial semi-wad cutter designs do well but I wanted something with a better ballistic coefficient.

There are several companies that will make custom molds from your designs but they can cost $200-$300 per mold. I set about to make my own. Lee Precision offers mold blanks that come with handles so I ordered a pair of those to get started. Lee Precision also has a guide sheet for creating drawings for them to make custom molds for customers. Armed with this info I set about designing a bullet.

This is the final design. These will be powder coated so I chose to use the Lee small lube grooves instead of a large lube groove or no lube groove. The theory is the bullets will be run through a final sizing die and I wanted the body to have a little room to compress without elongating the bullet if it had no grooves while keeping a larger surface area for barrel land engagement. The target weight with range lead & gas check is 155-160 grains.

To cut the mold I decided to make a one flute form tool from O-1 drill rod. Several HSS tool bits were needed to cut the various grooves and nose profile.

Tools from left to right are (1) basic turning/facing tool. (2) Nose form tool. This tool has a double radius, .075 at the tip and .312 beyond. I printed the profile at full scale, glued it to the tool bit blank and rough ground by hand on the bench grinder. Finishing was with a diamond bit in a die grinder. (3) Case crimp groove tool at 15 deg with a 90. (4) Lube groove tool, each side is 26 deg. (5) gas check relief tool at 3 deg.

1/2" drill rod turned to .359" ready for the nose form.

Nose profile cut.

Hand sanded w/320 to .358"

Crimp groove cut

Lube grooves cut

Gas check relief cut

Final profile

Last edited: