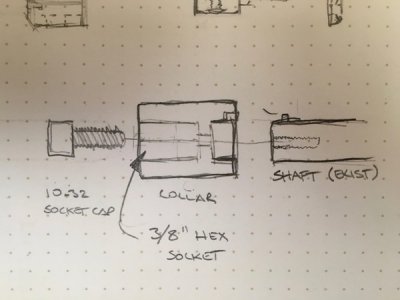

A part I'm making needs a blind hexagonal hole (think socket-cap screw). I need enough precision that I can rotate (drive) this part on its axis via a 3/8" ball Allen wrench as part of a low-speed power train.

Any ideas on how to approach this?

Any ideas on how to approach this?