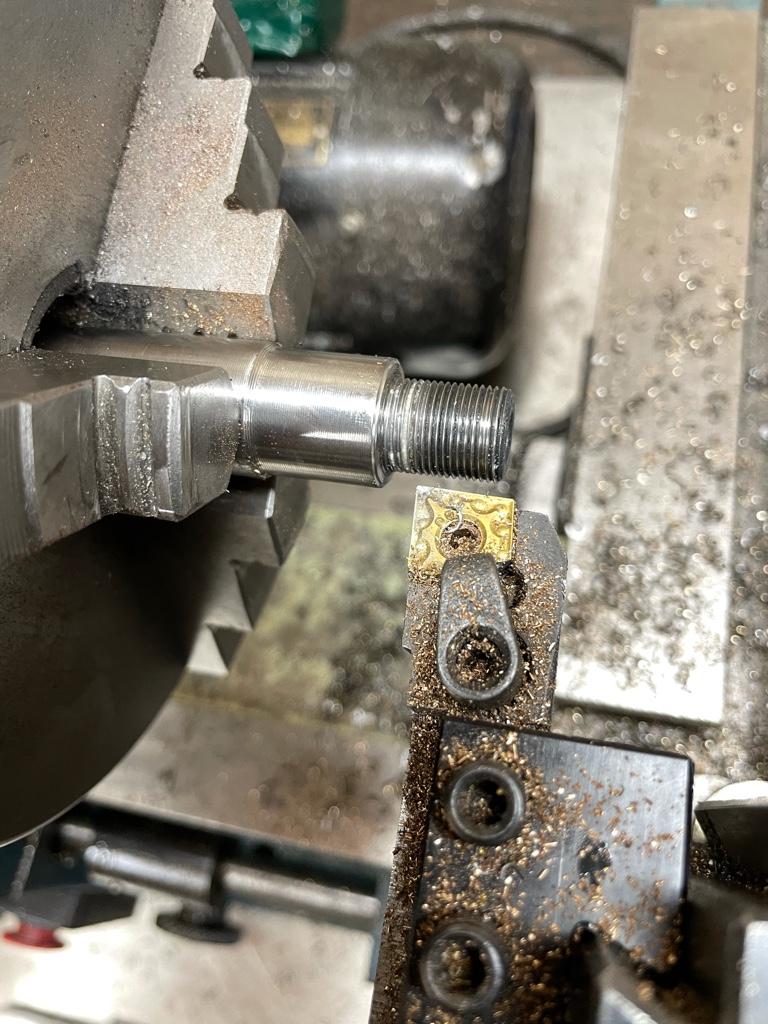

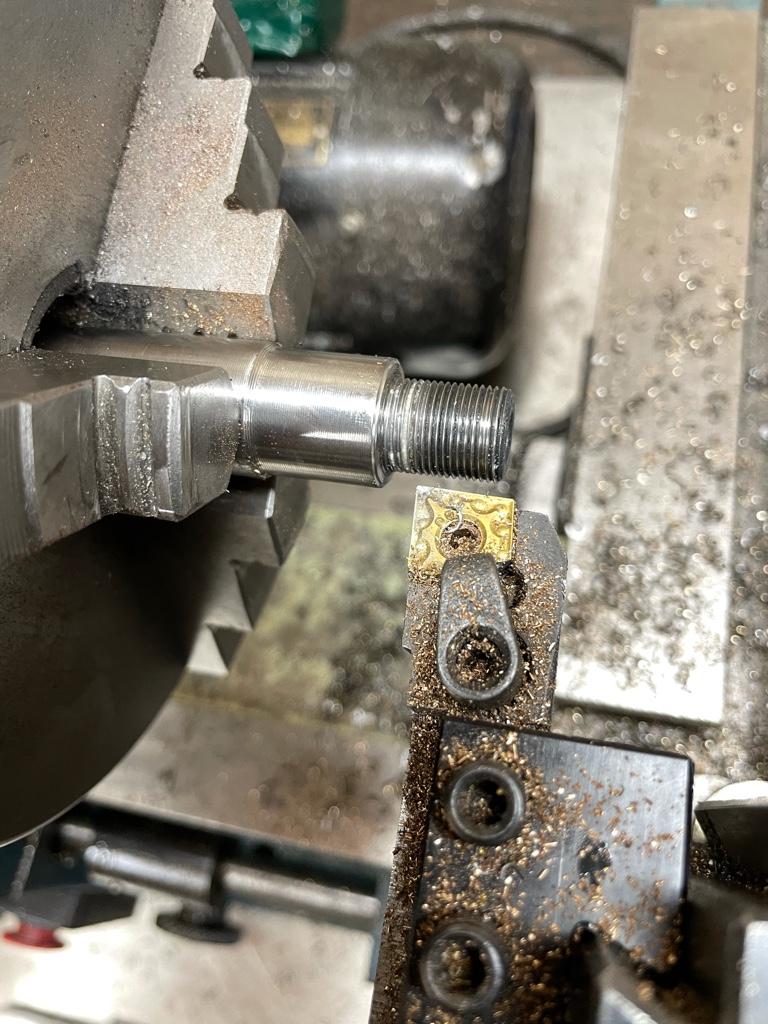

I used a HSS threading tool and cut threads on a junk .224 barrel from PSA (don’t wanna get into it). I’ve never cut threads and have muzzle devices that I don’t want to tear up.

What is best to cut a “good enough” crown with. ? I used like a 30 degree countersink but that’s a junk barrel so doesn’t matter.

Do you guys thread indicated off bore with a steady rest ? Or on centers ? Or don’t worry about it and just thread it close to chuck ???

I have a WAY out ruger factory barrel, 110 thousands off center, that tore up my 30 cal cab before .. warranty no longer covered bc company out of business, don’t wanna do that again. I ought to align those threads myself but the barrel is 16in and I “technically” can’t cut off and shorten it.

I should of never shot through a $1000 chunk of metal with that barrel.. hindsight 20/20.. back then when I first got can I was just excited and wanted to try it on everything

Thought of cutting threads off and retreading with a small bushing that is threaded 1/2x28. … or just don’t worry about it.

Sent from my iPhone using Tapatalk

What is best to cut a “good enough” crown with. ? I used like a 30 degree countersink but that’s a junk barrel so doesn’t matter.

Do you guys thread indicated off bore with a steady rest ? Or on centers ? Or don’t worry about it and just thread it close to chuck ???

I have a WAY out ruger factory barrel, 110 thousands off center, that tore up my 30 cal cab before .. warranty no longer covered bc company out of business, don’t wanna do that again. I ought to align those threads myself but the barrel is 16in and I “technically” can’t cut off and shorten it.

I should of never shot through a $1000 chunk of metal with that barrel.. hindsight 20/20.. back then when I first got can I was just excited and wanted to try it on everything

Thought of cutting threads off and retreading with a small bushing that is threaded 1/2x28. … or just don’t worry about it.

Sent from my iPhone using Tapatalk