- Joined

- Jul 9, 2018

- Messages

- 314

Much appreciate the drawings, I think i understand. Thanks

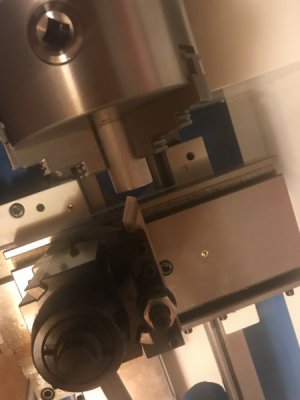

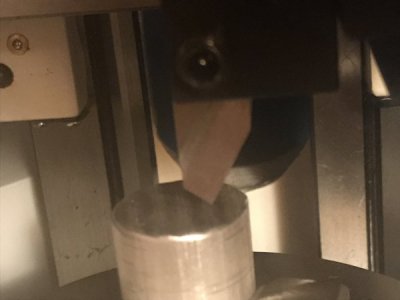

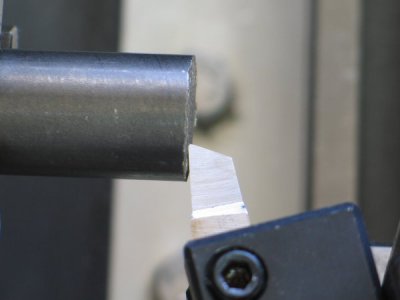

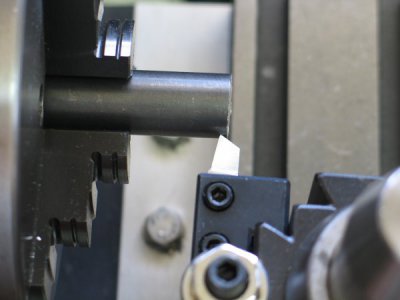

I am just trying to understand what end is up on some of these tools I have..lol

Luckily I can go slow and will practice with no tool 1st and get used to how the machine moves and operates.

really nice set of videos by MIT, I am on number 3 but will practice doing all the stuff in #1 to start off.

I am just trying to understand what end is up on some of these tools I have..lol

Luckily I can go slow and will practice with no tool 1st and get used to how the machine moves and operates.

really nice set of videos by MIT, I am on number 3 but will practice doing all the stuff in #1 to start off.