I'm not exactly sure why but I've had a bit of a fascination with shapers and gears. I've cut them on a cnc and I've printed them on 3d printers but there is something quite alluring about cutting perfect gears. Buying a set of gear cutters seems like cheating. Until recently the closest I've been to making a perfect gear was watching youtube videos. The theme in them appears to be that no one seems to know how to cut the tool's tip and what the proper depth is (related to the tip width).

Yesterday morning I rewatched someone making gears on a shaper and I got interested again so I poked around with openSCAD to try to simulate the process of shaping gears but I didn't have any luck and I don't think I really understand how it works. Then I looked around for alternatives and found CadQuery which was similarly difficult to learn but I managed to get something working. CadQuery is a python library and it has a GUI viewer called CQ-editor. You can run my script in it and mess with the results.

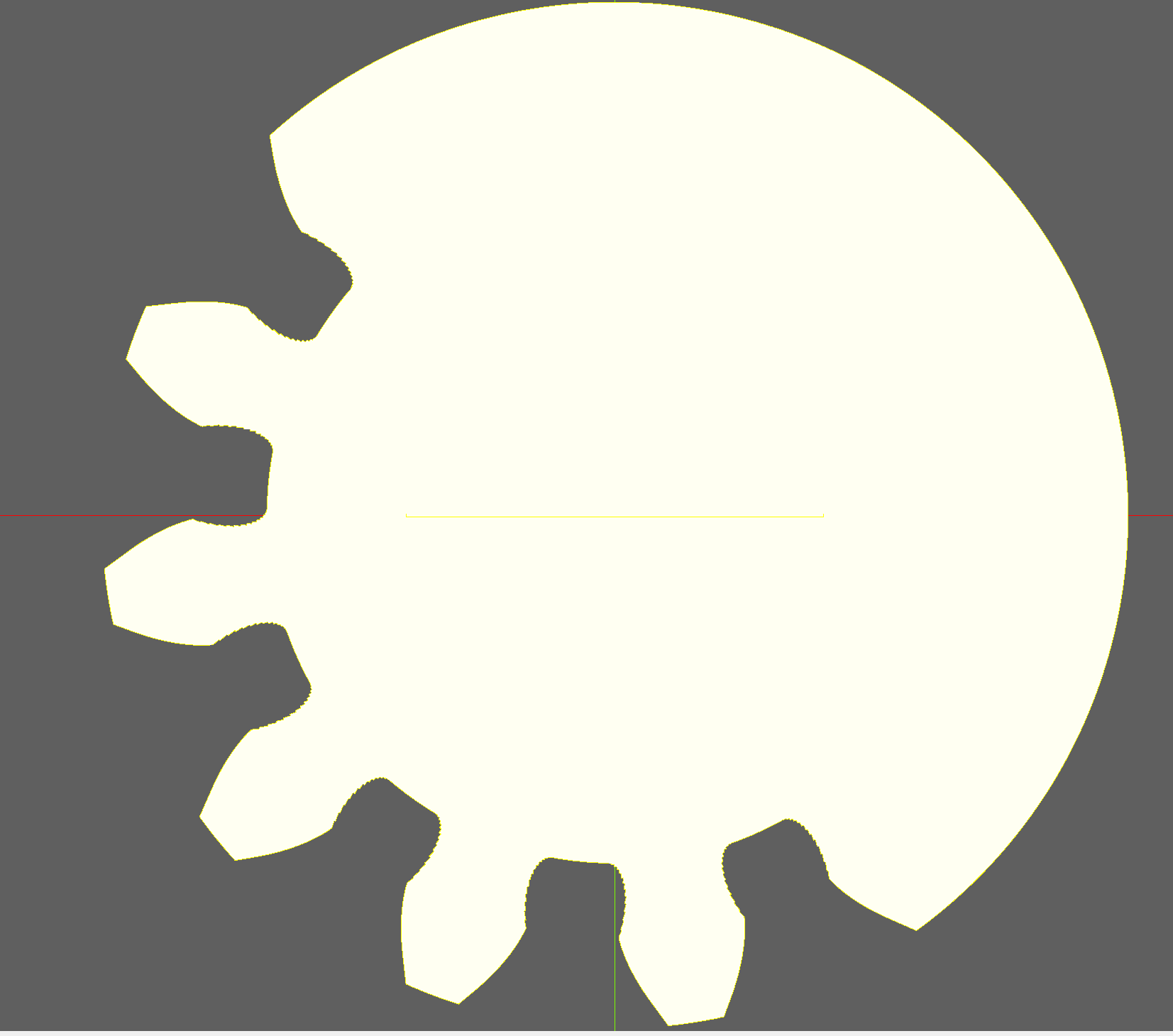

Here's a sample:

I'm wondering if I just keep it as a gist or if it requires it's own repository and any changes/features.

The source is here: https://gist.github.com/jschoch/39b7f7299f9205ce0cada857d0ec7861

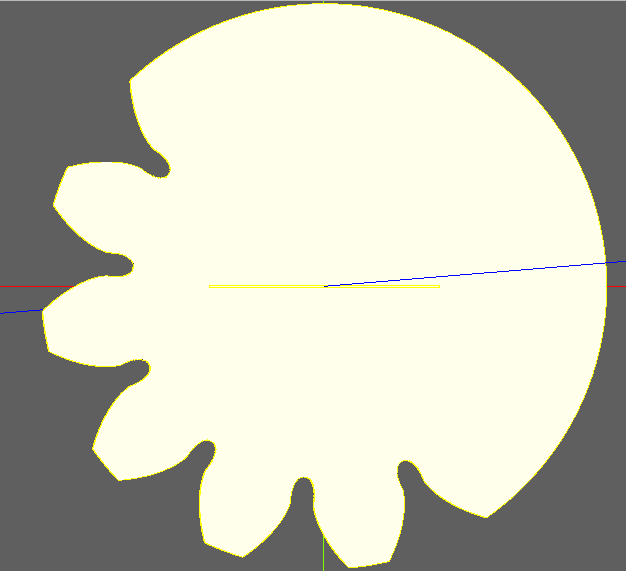

Here's an example of using tooltip that is too small.

Since there doesn't seem to be a way to measure the model directly you can import it into fusion 360 and measure it there. You can also generate a standard gear and compare the models.

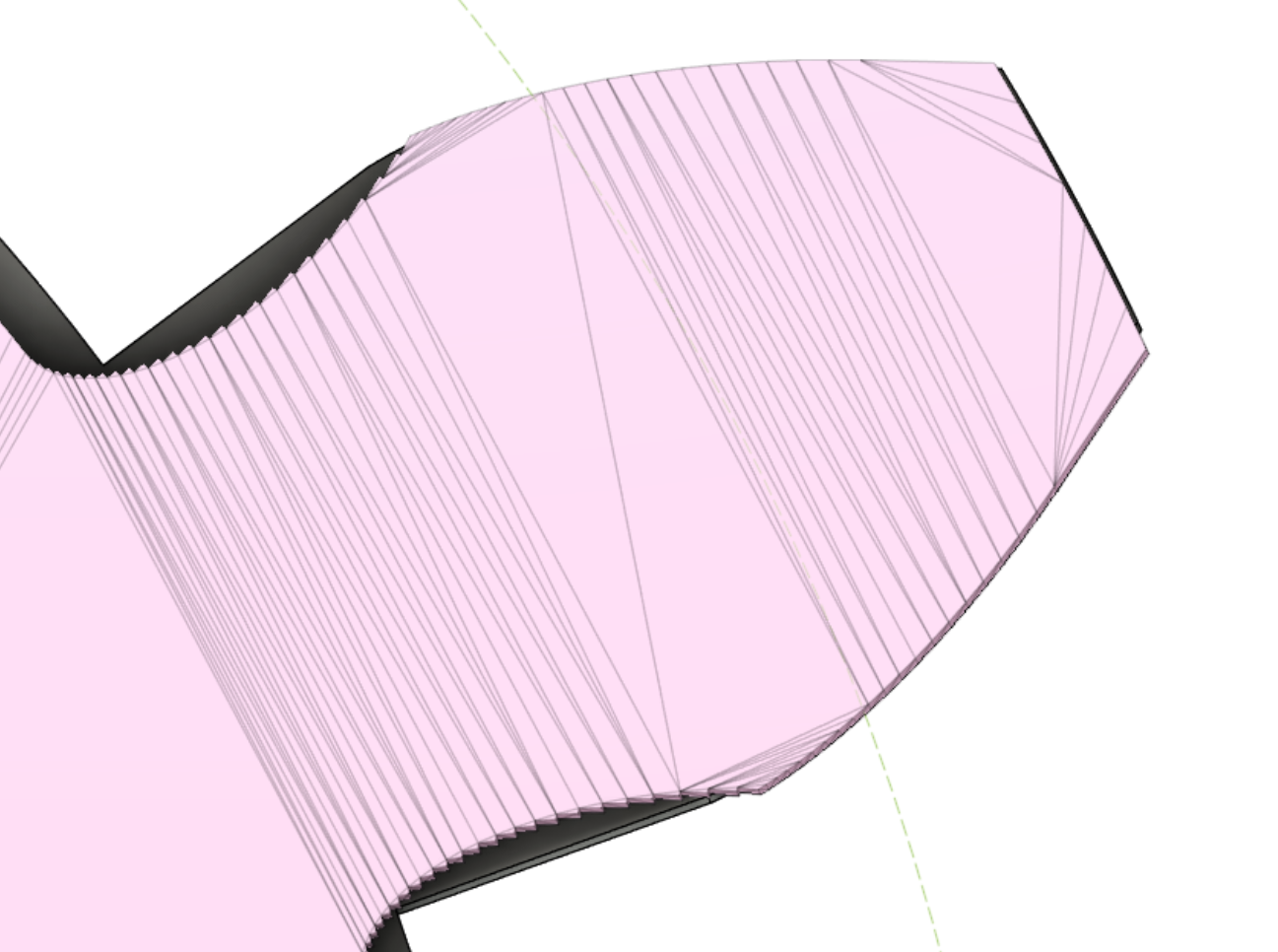

Here is an example: the purple is the simulated gear, the grey is the fusion generated gear. The program has a steps variable that you can set to reduce the sharp corners, this was run with a small number of steps. The steps would be single passes of the tool before the table ratchets over.

Hope this helps someone. I don't have a shaper but I could use one of my cnc lathe or mills to make small shaper cuts.

Yesterday morning I rewatched someone making gears on a shaper and I got interested again so I poked around with openSCAD to try to simulate the process of shaping gears but I didn't have any luck and I don't think I really understand how it works. Then I looked around for alternatives and found CadQuery which was similarly difficult to learn but I managed to get something working. CadQuery is a python library and it has a GUI viewer called CQ-editor. You can run my script in it and mess with the results.

Here's a sample:

I'm wondering if I just keep it as a gist or if it requires it's own repository and any changes/features.

The source is here: https://gist.github.com/jschoch/39b7f7299f9205ce0cada857d0ec7861

Here's an example of using tooltip that is too small.

Since there doesn't seem to be a way to measure the model directly you can import it into fusion 360 and measure it there. You can also generate a standard gear and compare the models.

Here is an example: the purple is the simulated gear, the grey is the fusion generated gear. The program has a steps variable that you can set to reduce the sharp corners, this was run with a small number of steps. The steps would be single passes of the tool before the table ratchets over.

Hope this helps someone. I don't have a shaper but I could use one of my cnc lathe or mills to make small shaper cuts.