- Joined

- Jun 7, 2019

- Messages

- 358

Setup and milling arcs and circular features is an interesting challenge for the manual machinist. I’ve gotten enamored with tools to do this job and the math and procedures to pull it off on complex parts. While even the simplest 2D CNC makes arcs and profiling easy, there are still some jobs that lend themselves to rotary tables. a small rotary table with a 3 jaw is very useful, but it’s really interesting to have a 12-18” table to provide enough space for hold downs etc…. Heavy duty rotary for milling:

Cutting gears really necessitates a dividing head and a matching tailstock, this one was rescued from a Navy ship.

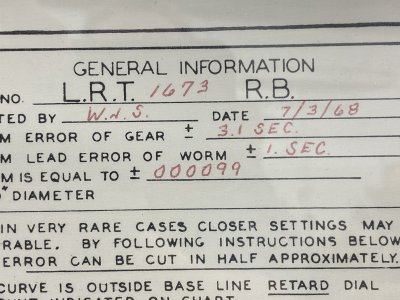

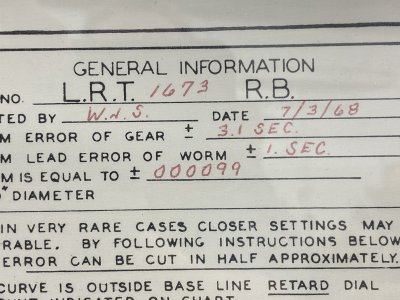

real angular precision for jig boring and jig grinding from Moore. This is a joy to use. Incredible accuracy for something 54 years old. Check out the certificate.

Cutting gears really necessitates a dividing head and a matching tailstock, this one was rescued from a Navy ship.

real angular precision for jig boring and jig grinding from Moore. This is a joy to use. Incredible accuracy for something 54 years old. Check out the certificate.