- Joined

- Oct 31, 2016

- Messages

- 2,643

Some of my projects will involve cutting metric threads and I wanted to figure out how to cut metric threads on my 12x36 lathe.

I know that there are numerous threads and videos about how to cut metric threads on an inch lathe all over the internet. I think that I have read most of them. There are mind numbing discussions about this gear or that gear and combinations thereof and error rates taken out 5 & 6 decimal places. But virtually all of the threads and youtube videos seem to assume that the reader already knows and understands how the gears work. Well for a newby like myself you are just stuck out in left field trying to figure this puzzle out. Especially how it works with a qcgb.

The first speck of light at the end of the tunnel came when I ran across a video on cutting metric threads through the qcgb on a South Bend model A 9 lathe.

What this guy did is gear his lathe so that his carriage moved 6mm instead of 1 inch in 8 revolutions of the spindle. I may be using some incorrect terminology here. To do this he geared his lathe so that the lead screw spun 1.89 times faster than normal using 54 & 80 gears instead of the normal 20 & 56 gears on his South Bend. With this change his lathe when set to cut 8 TPI now cut 6mm. 12 TPI cut 4mm, 16 TPI cut 3mm. 24 TPI cut 2mm, 32 TPI cut 1.5mm, 48 TPI cut 1mm, 64 TPI cut .75mm, 80 TPI cut .60mm, 96 TPI cut .50mm, 160 TPI cut .30mm and 192 TPI cut .25mm. I thought to myself why wouldn't this work on my 12x36.

I was now on a quest to figure out this intellectual challenge and was getting nowhere fast. Until I ran across a thread on this forum about slowing down the speed of the lead screw on a craftsman 12 with a qcgb. http://www.hobby-machinist.com/thre...on-a-qcg-late-model-12-craftsman-lathe.39019/ I want to give a huge thank you to Robert D for his explanation of how changing the gears effects the speed of the lead screw.

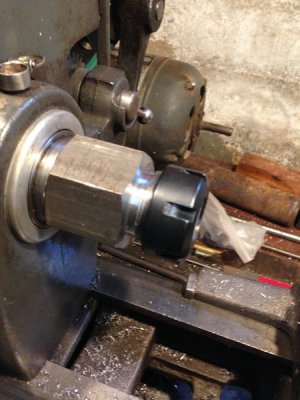

With this new found knowledge I set to trying different gearing until I found a combination of gears that would spin the lead screw approximately 1,89 times faster than normal. The closest that I have found so far is replacing the normal 40 gear with a combination 56/44 gear run off the inner 32 gear and replacing the normal 48 gear with a 40 gear. With this gearing the lead screw moves 5.988 mm in 8 revolutions of the spindle which is an error of only .002% if I got all of the math correct.

So am I totally lost here or did I figure this out correctly?

Chuck

I know that there are numerous threads and videos about how to cut metric threads on an inch lathe all over the internet. I think that I have read most of them. There are mind numbing discussions about this gear or that gear and combinations thereof and error rates taken out 5 & 6 decimal places. But virtually all of the threads and youtube videos seem to assume that the reader already knows and understands how the gears work. Well for a newby like myself you are just stuck out in left field trying to figure this puzzle out. Especially how it works with a qcgb.

The first speck of light at the end of the tunnel came when I ran across a video on cutting metric threads through the qcgb on a South Bend model A 9 lathe.

I was now on a quest to figure out this intellectual challenge and was getting nowhere fast. Until I ran across a thread on this forum about slowing down the speed of the lead screw on a craftsman 12 with a qcgb. http://www.hobby-machinist.com/thre...on-a-qcg-late-model-12-craftsman-lathe.39019/ I want to give a huge thank you to Robert D for his explanation of how changing the gears effects the speed of the lead screw.

With this new found knowledge I set to trying different gearing until I found a combination of gears that would spin the lead screw approximately 1,89 times faster than normal. The closest that I have found so far is replacing the normal 40 gear with a combination 56/44 gear run off the inner 32 gear and replacing the normal 48 gear with a 40 gear. With this gearing the lead screw moves 5.988 mm in 8 revolutions of the spindle which is an error of only .002% if I got all of the math correct.

So am I totally lost here or did I figure this out correctly?

Chuck