I had occasion last week to make an aluminum pulley for a project I was doing. The pulley was easy. The keyway was not. I am not interested in paying a couple hundred bucks for a broach set that I will only use once or twice in my lifetime.(plus the arbor press that I don;t have) I had read an article about chucking up the pulley in the lathe chuck, making a cutting tool (like for a shaper) and running the carriage back an forth to cut the pulley. It sounded good. Very quickly reality set in and I came to the conclusion that whomever had written the article I read about this concept was either lying about it or I entirely missed how he was doing it. I spent about 3 hours messing around with it. I ground cutter to go into a boring bar. After about 500 (at least is seemed like 500) passes back and forth with the cutter, I had a keyway about 25 thou deep. Perhaps the broach set is priced the way they are for a reason. Has anyone done this type of keyway cutting? Can anyone tell me how they cut keyways without a broach?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting Pulley Keyways - Without a Broach

- Thread starter Earl

- Start date

- Joined

- Oct 16, 2019

- Messages

- 6,570

I had occasion last week to make an aluminum pulley for a project I was doing. The pulley was easy. The keyway was not. I am not interested in paying a couple hundred bucks for a broach set that I will only use once or twice in my lifetime.(plus the arbor press that I don;t have) I had read an article about chucking up the pulley in the lathe chuck, making a cutting tool (like for a shaper) and running the carriage back an forth to cut the pulley. It sounded good. Very quickly reality set in and I came to the conclusion that whomever had written the article I read about this concept was either lying about it or I entirely missed how he was doing it. I spent about 3 hours messing around with it. I ground cutter to go into a boring bar. After about 500 (at least is seemed like 500) passes back and forth with the cutter, I had a keyway about 25 thou deep. Perhaps the broach set is priced the way they are for a reason. Has anyone done this type of keyway cutting? Can anyone tell me how they cut keyways without a broach?

I have done exactly what you did with the exception being that I used a HSS cutoff tool for the broach.

It took ages and was complicated by the fact that it was a blind hole so the swarf had no where to go.

Took me ages.

I became a believer in a broach set after that. But I still don’t own a set.

Thank you very much for your response. I thought that it was me. At the rate that I was removing metal (aluminum) it would have taken a couple of days to get that keyway done. I ended up with a set screw and a dimple on the shaft to keep the pulley from slipping. I think that if I ever have the need to do another pulley, I will spring for the broach or just buy the pulley.I have done exactly what you did with the exception being that I used a HSS cutoff tool for the broach.

It took ages and was complicated by the fact that it was a blind hole so the swarf had no where to go.

Took me ages.

I became a believer in a broach set after that. But I still don’t own a set.

- Joined

- Nov 28, 2016

- Messages

- 2,344

I bought broaches in the sizes I need from Shars... they are around $30 each... the bushings are $5 to $10 each, or you can make your own from aluminum. I have used them without a press by tapping the broach through with a brass hammer... don't hit it hard, just tap, tap, tap... you will be able to tell how hard you need to tap on it.

This will cut your keyway in 5 minutes, for less than $40 plus shipping.

-Beat

This will cut your keyway in 5 minutes, for less than $40 plus shipping.

-Beat

Earl,I had occasion last week to make an aluminum pulley for a project I was doing. The pulley was easy. The keyway was not. I am not interested in paying a couple hundred bucks for a broach set that I will only use once or twice in my lifetime.(plus the arbor press that I don;t have) I had read an article about chucking up the pulley in the lathe chuck, making a cutting tool (like for a shaper) and running the carriage back an forth to cut the pulley. It sounded good. Very quickly reality set in and I came to the conclusion that whomever had written the article I read about this concept was either lying about it or I entirely missed how he was doing it. I spent about 3 hours messing around with it. I ground cutter to go into a boring bar. After about 500 (at least is seemed like 500) passes back and forth with the cutter, I had a keyway about 25 thou deep. Perhaps the broach set is priced the way they are for a reason. Has anyone done this type of keyway cutting? Can anyone tell me how they cut keyways without a broach?

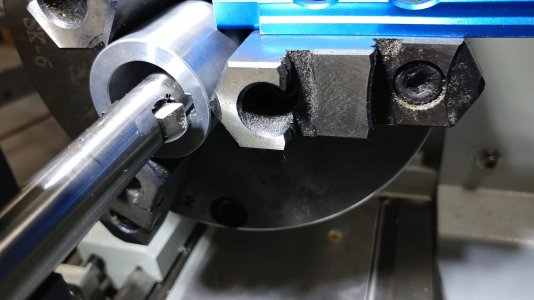

I made a lathe tool to broach bushings on an R8 Stub Milling Arbor like the one below:

The tool is similar to your description. The cutting edge is a small HSS square inserted in a 440C SS holder as you can see in the following video and pictures. I never did any broaching before and I did not want to buy a set before getting some idea and feel for broaching. The results were very good as can be seen by the nice chips generated.

Starting the process

Some progress

Almost final depth

Nice fit!

Broaching tool and mounting in BXA holder. Nice size curling chips on the bottom

I hope this helps.

Ariel

- Joined

- Nov 5, 2016

- Messages

- 1,419

I have dragged keyways in steel with success before. I use boring bars with a cutter ground to do cuts on the pull stroke, not push stroke. In fact, it was one of my first jobs when I first started working in the machine shop. That job was a blind keyway so a hole was drilled at the start position so the tool could be fed out to take the next cut. That's why it couldn't be broached (blind hole).

I don't know how ridged your lathe/setup is, but seems like it shouldn't have been too big on an issue to cut a keyway in aluminum. Maybe it was the way your tool was ground??? I like putting a roll on the top so the chip curls up on the way out... And plenty of good cutting oil in steel.

Ted

I don't know how ridged your lathe/setup is, but seems like it shouldn't have been too big on an issue to cut a keyway in aluminum. Maybe it was the way your tool was ground??? I like putting a roll on the top so the chip curls up on the way out... And plenty of good cutting oil in steel.

Ted

- Joined

- Nov 5, 2016

- Messages

- 1,419

Also, a lot of guys cut internal keys by dragging on their vertical mills...

Ted

Ted

- Joined

- Dec 23, 2019

- Messages

- 1,138

I've cut involute splines on my lathe using a boring bar and the compound turned parallel to the bed. The trick for me was to remove the leadscrew from the compound and rig up a lever from the back of the saddle running past the back of the compound and out to where I could tuck it under my arm. Feeding a thou at a time using the cross slide actuating the compound by moving myself side to side worked very well and it turned out to be a surprisingly easy operation. It works like a mini shaper or keyseater.

Good idea, maybe a drill press will work too.Also, a lot of guys cut internal keys by dragging on their vertical mills...

Ted