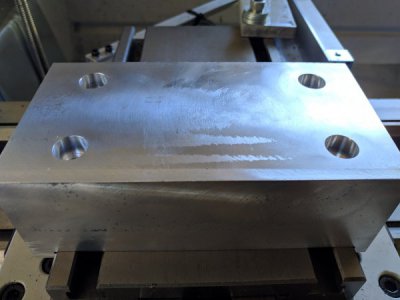

Thanks for the great tips on making holes in things! This stage of the project is perfect. 4 holes into t-nuts holding the block down. Everything dropped together perfectly. Spotting drill, then drilled with a cobalt M42 X size drill. I dropped down to about 2000 RPM to lower the pucker factor.

No more crap drill bits. These are from Drill Hog and make the HF set look like I was trying to drill with a screwdriver. Figured I already had them, but no more. I'll use them for wood or something.

Now I need to tinker with the boring head so I can cut counterbores for them. I guess I could use a larger end mill, but I think it will make a good learning project, after testing on scrap of course!

No more crap drill bits. These are from Drill Hog and make the HF set look like I was trying to drill with a screwdriver. Figured I already had them, but no more. I'll use them for wood or something.

Now I need to tinker with the boring head so I can cut counterbores for them. I guess I could use a larger end mill, but I think it will make a good learning project, after testing on scrap of course!