- Joined

- Jul 15, 2020

- Messages

- 421

This is far from being a new idea, but it worked so well for me that I thought I would share it.

The standard approach for cutting small or short material in a 4 x 6 or 7 x 12 bandsaw is to extend the jaws, and install a jackshaft or put an object of equal width at the other end of the vise. That approach requires minor modification to the saw, which has to be reversed in order to cut bevels.

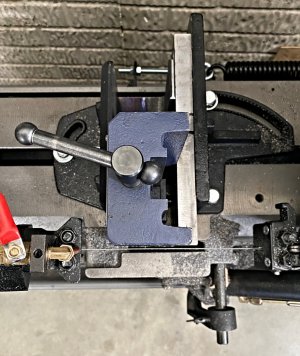

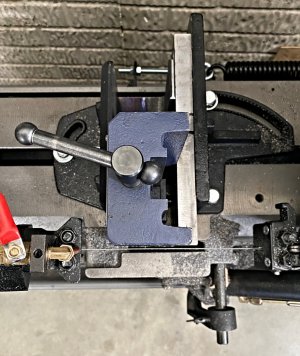

The method I chose for my 7 x 12 Jet saw was to use a drill press vise standing vertically to hold the part. The vise I used requires an 8" length of 4" wide cold roll steel bar about 8" long as shown in the photos. I used 3/4" thick steel, as that was what I had on hand, but anything 1/2" or more thick would work.

The 4" Palmgren vise I used was inexpensive, with a tight movable jaw that stays straight when clamped on only one side of the jaws. I also cut a piece of angle iron with one leg the same width as the body of the vise. The movable jaw can still be adjusted when the little vise is clamped in the saw vise.

These items can be placed on the saw or removed in seconds, and require no modification whatsoever to the saw. See pictures below:

The standard approach for cutting small or short material in a 4 x 6 or 7 x 12 bandsaw is to extend the jaws, and install a jackshaft or put an object of equal width at the other end of the vise. That approach requires minor modification to the saw, which has to be reversed in order to cut bevels.

The method I chose for my 7 x 12 Jet saw was to use a drill press vise standing vertically to hold the part. The vise I used requires an 8" length of 4" wide cold roll steel bar about 8" long as shown in the photos. I used 3/4" thick steel, as that was what I had on hand, but anything 1/2" or more thick would work.

The 4" Palmgren vise I used was inexpensive, with a tight movable jaw that stays straight when clamped on only one side of the jaws. I also cut a piece of angle iron with one leg the same width as the body of the vise. The movable jaw can still be adjusted when the little vise is clamped in the saw vise.

These items can be placed on the saw or removed in seconds, and require no modification whatsoever to the saw. See pictures below: